|

|

02-01-2017, 01:50 AM

02-01-2017, 01:50 AM

|

#21

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Fuel issues- Tubing info

So, I pressurized the fuel tank - first I blast it good to get mud daubers out of vent lines, then plugged vent line with a bolt and shot 5 psi in tank.

Was like a fountain...anywhere there was a radius, she sprayed- about 4-5 spots. Close inspection under the corrugated wire hose cover revealed cracks. If fuel is coming out.... air is getting sucked in.All the new additives/alcohol/methanol/bio gunk they add to fuels now to increase their profits just eat our hoses and seals.

It's already got 1/2 line all the way to lift pump, 3/8 return and 5/16 for genset. Nothing kills like overkill, I always say.

1) Did some research, the best stuff out there is the hard lines- steel or stainless, but Swagelok fittings are pricey and brass won't compress stainless....No copper or aluminum- vibrations work harden and crack.

1/2''Dia X .035 X 100ft Type 316L coiled Stainless Steel Tubing .65/foot on ebay.

2) PTFE (Teflon) lined braided hose- good for ridiculous pressures and impervious to chemicals, good to 500 degrees. Needs special aluminum fittings=no barb fitting recycle. Lifetime stuff, used in racecars- even brake lines. Fittings killed the deal, pricey. Pandababy2007 has kits on ebay

3) Trident Rubber makes USCG marine hose that is lined to protect the rubber called TYPE A1 BARRIER LINED - can use existing fittings and is about $2/ foot an Amazon.

I don't want to repeat this job every 13 years, don't want air in the lines and don't want degraded rubber in my fuel.

May have to drop the 175 lb tank to see what is going on up there, will stick borescope camera in there before committing to that.

|

|

|

02-15-2017, 10:23 PM

02-15-2017, 10:23 PM

|

#22

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Interior

Almost done with the interior- came out nice. Found a couple couches at Goodwill and some cabinets at Lowes.

|

|

|

02-16-2017, 01:53 AM

02-16-2017, 01:53 AM

|

#23

|

|

Bus Geek

Join Date: Oct 2005

Location: Clearlake, Northern California

Posts: 2,511

Year: 1992

Coachwork: Blue Bird

Chassis: TC-2000 Frt Eng, Tranny:MT643

Engine: 5,9 Cummins

Rated Cap: 84

|

Paging George Pullman. George Pullman to a gilded courtesy telephone please.

__________________

|

|

|

02-16-2017, 12:11 PM

02-16-2017, 12:11 PM

|

#24

|

|

Bus Crazy

Join Date: Aug 2014

Location: SW New Hampshire

Posts: 1,334

|

Quote:

Originally Posted by Elliot Naess

Paging George Pullman. George Pullman to a gilded courtesy telephone please.

|

Where's the "like" button?

|

|

|

02-16-2017, 03:41 PM

02-16-2017, 03:41 PM

|

#25

|

|

Skoolie

Join Date: Oct 2015

Location: Columbus, Ohio

Posts: 142

Year: 1992

Coachwork: Fisher Body

Chassis: GM "B" Platform

Engine: 350 TBI Chevrolet

Rated Cap: 8

|

Wow, what great work! That was really Quick!

__________________

Closest I have to a Bus would be my '92 Oldsmobile Custom Cruiser Station Wagon 1 of 4,347 built.

|

|

|

02-16-2017, 05:54 PM

02-16-2017, 05:54 PM

|

#26

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by Stewzer55

Wow, what great work! That was really Quick!

|

Yeah, turned-out ok. The granite inlay was tough, but it works. Bus looks a lot bigger with that lens, too.

|

|

|

05-31-2017, 01:28 PM

05-31-2017, 01:28 PM

|

#27

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Update on fuel system- Great News !

Update on fuel system- Great News !

Been awhile since I updated my page and much has happened. I need to get my photos off old phone to add later.

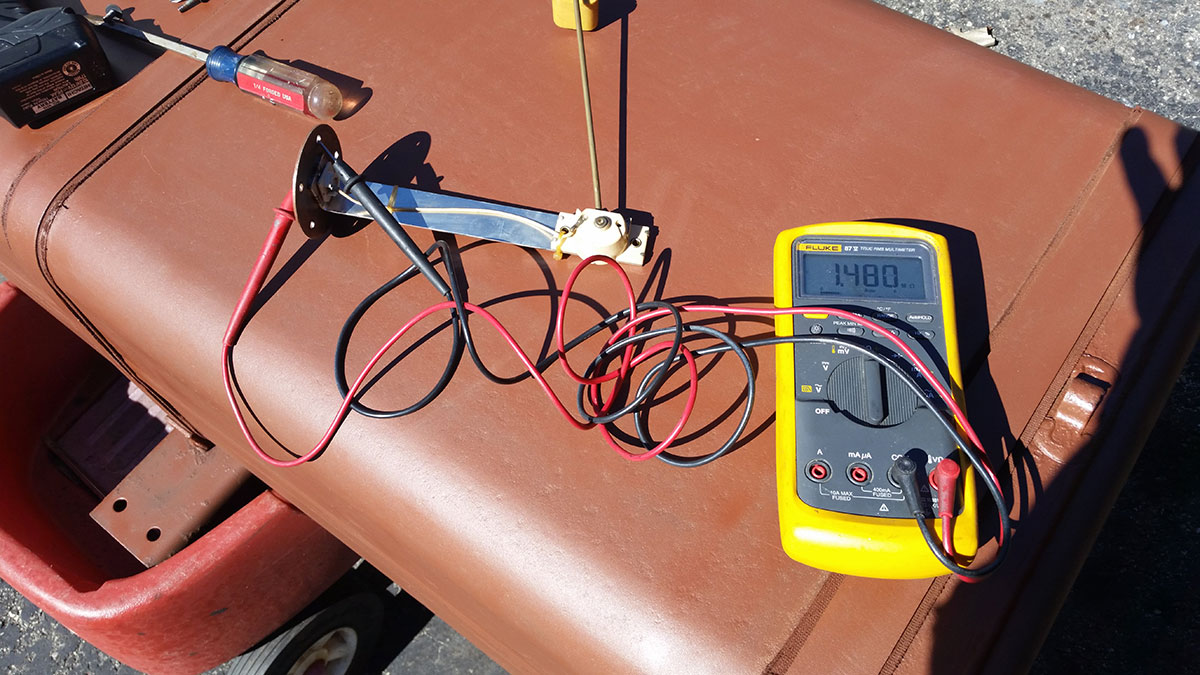

I drained the fuel tank- thought it was empty, was 60 gallons full of clean fuel, so I put that in my other truck. Fuel gauge sender was busted, so a million bolts later, I dropped the fuel tank in the driveway. I got it out and cleaned, sanded, primed, painted outside of fuel tank. Inside was spotless- $25 USB borescope cameras are great! Cleaned bad sender with brake cleaner, now tested fine, reinstalled- I have no floor access hole like most.

They had funky designed shared fuel delivery system for engine and 10K Genset, so I started all over from the diptube and added separate drawtube for genset to isolate fuel lines as they were shared/spliced previously.

I relocated the fuel pump to the rear of the bus and installed a AirDog Raptor and reused the large separator/filter before the pump. Raptor has adjustable pressure and moving pump off hot engine will help it's life, not to mention better at pushing vs pulling fuel. Fuel gauge for dash on order w/ alarm.

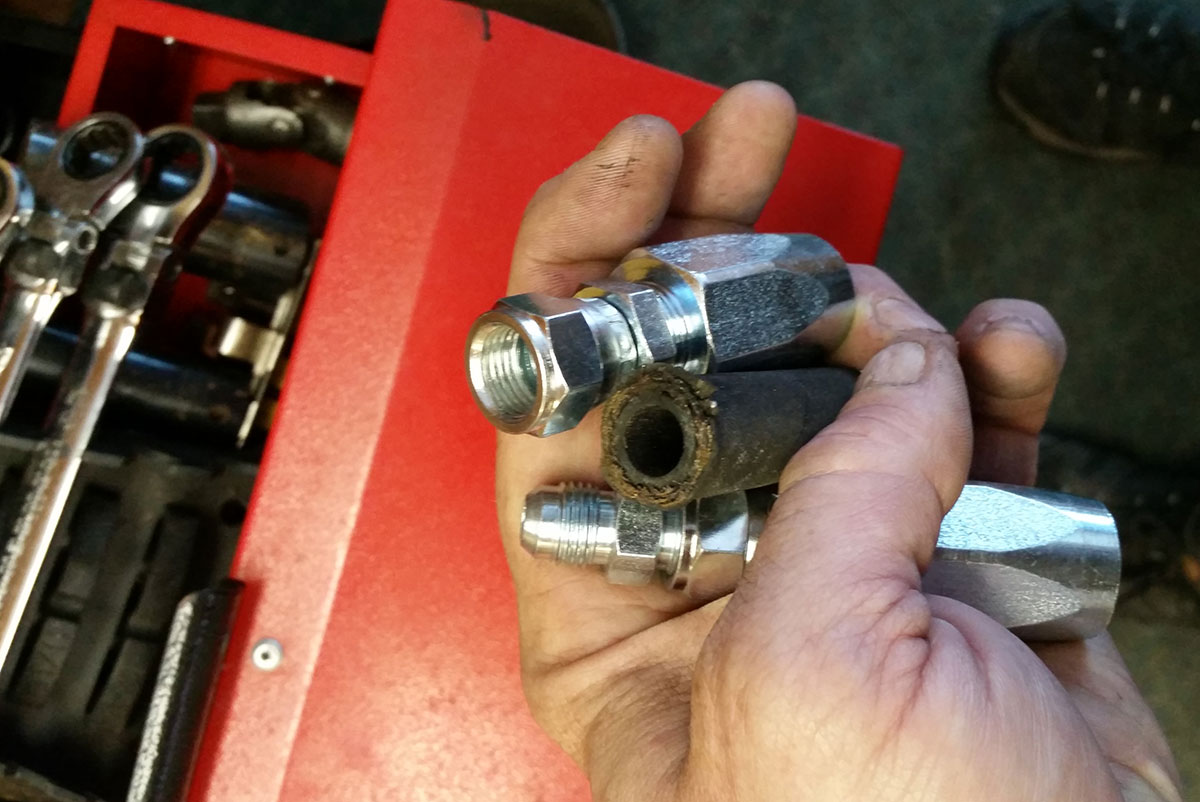

New Lift Pump and lines/fittings was ~$500, peace of mind: priceless

All new fuel lines are 2 wire hydraulic line, which is 3000PSI for backhoes and such and all connections are JIC AN fittings. I didn't use any push-lock or hose clamps as those eventually fail/suck air. Needed to get a few specialty fittings from a auto race shop - metric straight 12x1.5 MM thread to -6 AN. Removed old line and slid new line into the many clamps and zip ties. Extended the electrical connection for fuel pump from engine to rear of bus and secured.

bumped the starter, waited 15 sec.....bump again, wait.... giver her a shot- boom ! she fired up ! Tighten injectors and Woot ! I have a bus now and not a giant immobile POS in the driveway. Aired-up, all systems-Go ! Engine sounds super strong (only 26k miles) and turbo whistles a nice song.

She purrs like a kitten- slipped the MD3060 in drive and took it for my first drive ! I never drove a bus this size before- is long. Drives real smooth, super quiet inside considering with a busted exhaust clamp it is running open-headers outside. Plenty peppy for me, but I only drove around the neighborhood. Got some looks- we don't see Bookmobiles out here much. I had my toolboxes inside and boy did they clatter on her maiden voyage.

I have more mechanicals to tend to before I buy my solar panels, OSB and rockwool  Finish new genset fuel line, fluids/filters for that. Fix exhaust. Repair automatic step- as it is stuck in out position.

All-in-all, good a good day. Am more than tired of laying under that bus.

|

|

|

05-31-2017, 02:35 PM

05-31-2017, 02:35 PM

|

#28

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,848

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

super cool!!! peace of mind fixes are good!! something you kniw is now done right so you can just go!..

now you will want to just cruise it all over town!

-Christopher

|

|

|

06-09-2017, 12:12 AM

06-09-2017, 12:12 AM

|

#29

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

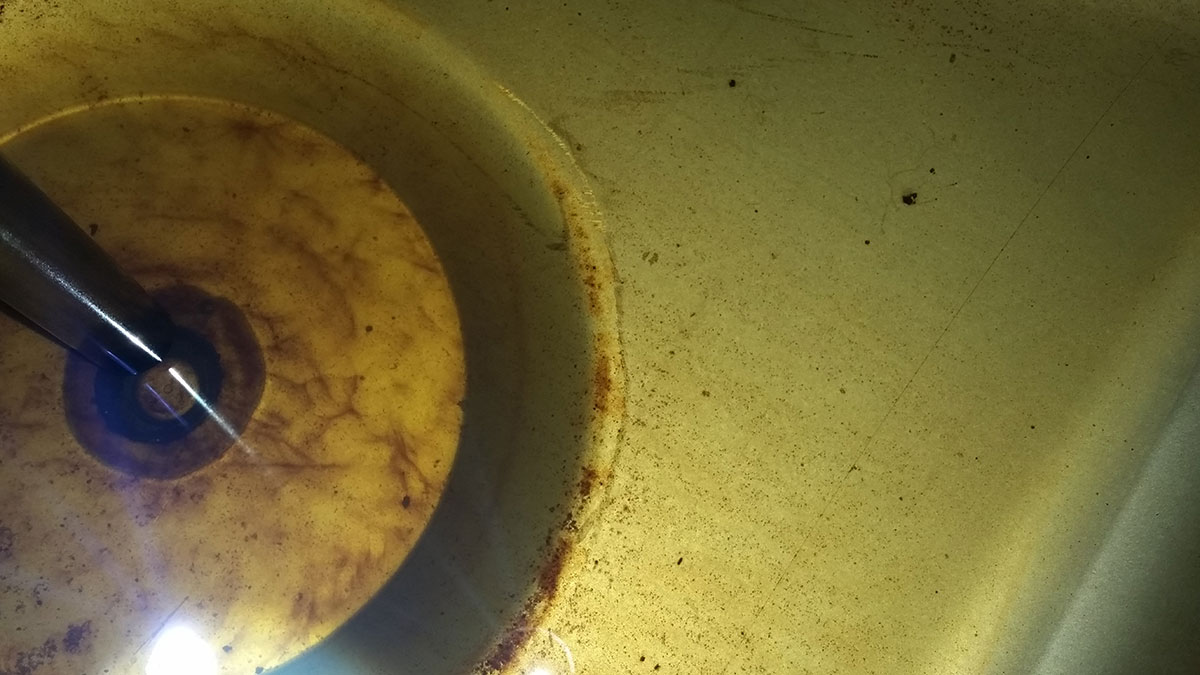

Here are some of the pics of the fuel tank rejuvenation project. It was the rustiest part of the whole bus and critical to be functioning properly.

Dirty rusty fuel tank, leaking, cracked lines- yuck.

Supposedly old fuel was oddly clear- had 60 gallons, pumped into other truck, burns fine. Interior of tank very clean, but bus has only had 50 tankfuls of fuel over it's boring life.

Primed and sender fixed. Ready for skoolie's best friend- Rust-Oleum.

|

|

|

06-09-2017, 09:05 AM

06-09-2017, 09:05 AM

|

#30

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

An access hole for the sender sure would be handy. Nice job and glad to hear it's purring.

|

|

|

06-09-2017, 06:32 PM

06-09-2017, 06:32 PM

|

#31

|

|

Bus Nut

Join Date: Sep 2016

Location: Chapel Hill, NC

Posts: 855

Year: 2002

Coachwork: Blue Bird

Chassis: All American

Engine: Cummins 8.3/Allison MD3060

Rated Cap: 84

|

Quote:

Originally Posted by Rusty

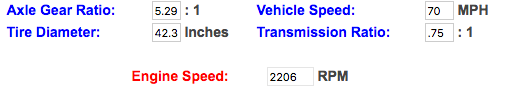

As it sits, with 5.29, 39" tall tires and 1:1 Transmission Ratio, poor little 5.9L would be spinning 2700 RPM to cruise 60 mph.

Get 6th gear unlocked @.75 , gives me 2051 rpm@60 mph. Still tiny bit high for mpg, but doable.

or swap the rear/carrier for rebuilt for $1500. 4.38 rear gets me 1980 rpm@70 mph with unicorn .75 final drive...not bad. 1:1 final gets me 2260 rpm...bit loud.

So ideally, I need to unlock top gear and swap diff --or 2-speed transaxle would be sweet, but is heavy work. |

To my knowledge, the MD3060 was only available with one set of ratios. Please correct me if I'm wrong.

I think you'll find that you already have an overdrive. Fifth gear should be .75, and if you unlock sixth, you'll have a .65 double overdrive.

|

|

|

06-09-2017, 09:51 PM

06-09-2017, 09:51 PM

|

#32

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by Rameses

To my knowledge, the MD3060 was only available with one set of ratios. Please correct me if I'm wrong.

I think you'll find that you already have an overdrive. Fifth gear should be .75, and if you unlock sixth, you'll have a .65 double overdrive.

|

Nope, you are correct, I was mistaken earlier on. 6th is locked now, verified today, but will get unlocked when street-legal as I have a short rear-end and need to lower the rippem's until I swap carriers.

|

|

|

06-09-2017, 10:04 PM

06-09-2017, 10:04 PM

|

#33

|

|

Bus Nut

Join Date: Sep 2016

Location: Chapel Hill, NC

Posts: 855

Year: 2002

Coachwork: Blue Bird

Chassis: All American

Engine: Cummins 8.3/Allison MD3060

Rated Cap: 84

|

Quote:

Originally Posted by Rusty

Nope, you are correct, I was mistaken earlier on. 6th is locked now, verified today, but will get unlocked when street-legal as I have a short rear-end and need to lower the rippem's until I swap carriers.

|

I just punched your numbers in an rpm calculator and have you turning 2075 at 70 mph if you unlock sixth. With a 5.9, that's good. I wouldn't change the ring and pinion if it were me.

|

|

|

06-09-2017, 10:12 PM

06-09-2017, 10:12 PM

|

#34

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Thanks for running the numbers- I intend to get that .65 gear and don't forsee a problem.

|

|

|

06-09-2017, 10:42 PM

06-09-2017, 10:42 PM

|

#35

|

|

Bus Nut

Join Date: Sep 2016

Location: Chapel Hill, NC

Posts: 855

Year: 2002

Coachwork: Blue Bird

Chassis: All American

Engine: Cummins 8.3/Allison MD3060

Rated Cap: 84

|

Quote:

Originally Posted by Rusty

Thanks for running the numbers- I intend to get that .65 gear and don't forsee a problem.

|

Out of curiosity, what size tires do you have that're only 39" tall?

|

|

|

06-10-2017, 07:10 AM

06-10-2017, 07:10 AM

|

#36

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by Rameses

Out of curiosity, what size tires do you have that're only 39" tall?

|

Good point, Rameses- I had used a tape measure, but they are 11R22.5, so... they really should be a bit taller:

To compute the approximate size of an 11R22.5: Tire sidewall height = 11 inches (tire width) X 90% (tire profile) X 2 (two sidewall sections, one above the wheel, one below) + 22.5 inches (wheel diameter)

11 X .90 = 9.9" X 2 = 19.8" + 22.5" = 42.3"

New calculations with the *corrected tire size and 5.29 gears would yield:

With locked 6th and only single OD avail:

Unlocking 6th gets .65 final:

I hope this is finally correct....

|

|

|

06-10-2017, 08:12 AM

06-10-2017, 08:12 AM

|

#37

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,848

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

using a tape measure accounts for the tire squash that occurs with the weight on it.. circumference is what affects wheel speed. I wouldnt worry about changing the carrier out if you get 6th unlocked, if you have driveline vibe from the fast spinning driveshaft you may need to get them balanced.. tires vary a bit from manufacturer.. my uniroyals are 41.3" as listed in the brochure.. I think 10R22.5 tires are close to 38-39 inches..

-Christopher

|

|

|

06-27-2017, 10:46 PM

06-27-2017, 10:46 PM

|

#38

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Update Summer

Here are some updates- either I'm working on the build...or updating. So no updates means I'm a working !

These are the JIC AN fttings and 3/8 hydraulic hose used for fuel. Cut it with a angle grinder. 25 feet and 2 fittings was $70 on ebay.

|

|

|

06-27-2017, 10:52 PM

06-27-2017, 10:52 PM

|

#39

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

I'm committed now...

So I took the crowbar and removed the 13 or so bookshelves. They were screwed to the wall horizontal studs and just resting on the floor. Made for easy removal, just had to pop solid maple trim piece.

My neighbor took all the shelves for his shed, was happy camper. My bus is thousands of pounds lighter as these were 3/4 plywood sandwich.

|

|

|

06-27-2017, 10:56 PM

06-27-2017, 10:56 PM

|

#40

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

My walls

Here are my walls with sprayfoam and flex conduit. I'll have to relocate a few of those to install windows.

Horizontal 2x4's secured the cabinetry- I will leave those and may sprayfoam the void.

I found a bit of water damage by lift door. Will have to replace few square feet of plywood floor.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|