|

|

09-13-2016, 01:46 PM

09-13-2016, 01:46 PM

|

#81

|

|

Skoolie

Join Date: Jun 2016

Location: Texas

Posts: 160

Year: 1997

Chassis: Saf-T-Liner MVP ER

Engine: Cummins 5.9L Diesel Engine

Rated Cap: 83

|

Quote:

Originally Posted by M1031A1

Justin,

I've spent the $170 to relocate my heater hose to below the floorboards and am re-routing the front heater to go straight down from the heater core to the new hose below the floor via new galvanized steel pipes. I'm connecting the under-seat heaters (2) the same way - through the floorboards - and also connecting my Webasto heater to the system in such a way as to have the option to isolate the engine when we're boon-docking, but open the system when it's cold and need to warm the engine up before starting.

I'll have that system going later this fall. Right now it's too hot to work on the electrical system during my mid-day breaks. I'll post my progress on my thread (hopefully in time to help you with your bus) as conditions allow.

M

|

Thats a cool idea. So you have the hoses running under the bus? I am very interested to see how that all shapes up.

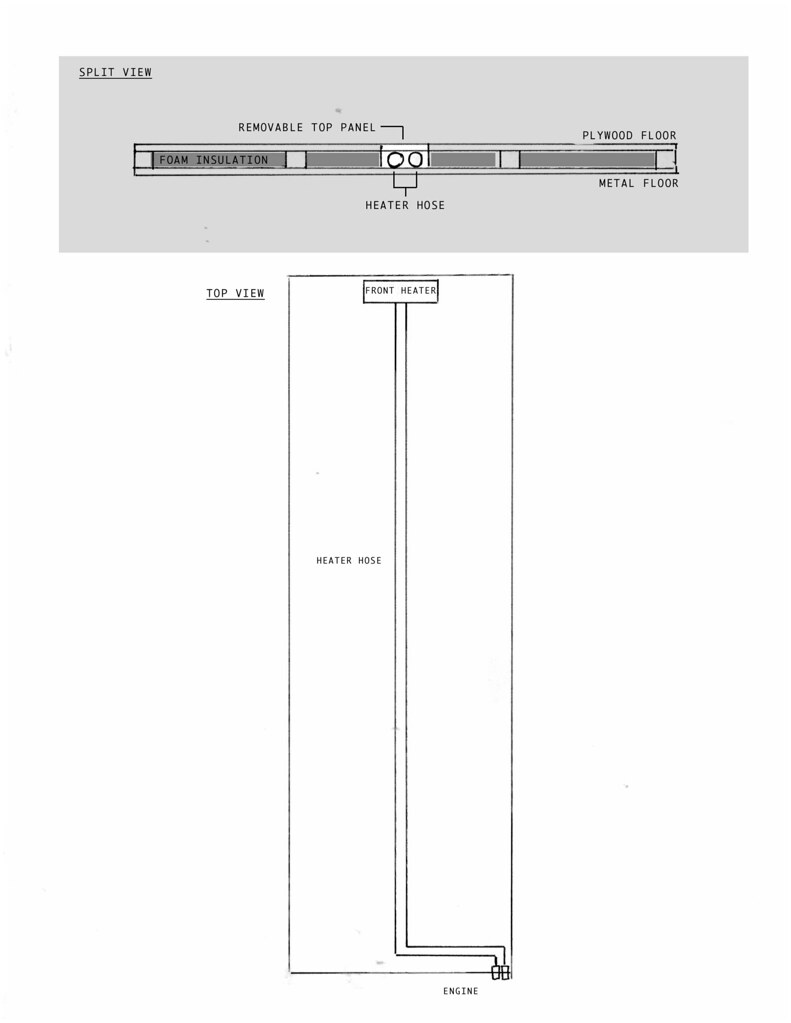

It actually gave me an idea that I quickly sketched up here:

It does not solve the heater hose cost, but it does allow me to maintain access to the hoses in case they need repaired/replaced. The hoses will basically run along the metal floor in the center of the bus. I will then build the sub floor around it, with a removable board to allow access the heater hose compartment in the middle of the bus.

Maybe I am being over paranoid about the heater hose failing on me, but I can see that being a mess if its impossible to get to.

|

|

|

09-13-2016, 02:17 PM

09-13-2016, 02:17 PM

|

#82

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,830

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

I would say if I were converting fully i would definitely run the heater lines under the bus.. but insulate them... otherwise with wind whipping over them you'll lose a ton of heat.. I'd put them inside some Line-hide at least... I dont have a pic of mine where i ran my A/C ducts to the rear inside it but here is a link to biy it... it snaps together quite tight so you could conceal your heater lines in it but still take it apart to replace them..

DiversiTech 230 D3 78 Long 3 SpeediChannel Line Set Cover

-Christopher

|

|

|

09-14-2016, 04:09 AM

09-14-2016, 04:09 AM

|

#83

|

|

Bus Crazy

Join Date: Dec 2014

Location: Dowdy Lakes, Colorado

Posts: 1,444

Year: 1989

Coachwork: Thomas

Chassis: Saf-T-Liner ER

Engine: 3208 CAT/MT643 tranny

Rated Cap: 87

|

Justin,

I'm running the hose inside the frame rail under the floor boards. Pics and details coming soon.

M

__________________

Firearms stand next in importance to the Constitution itself. They are the American people’s liberty teeth and keystone under independence. — George Washington

|

|

|

09-14-2016, 11:02 AM

09-14-2016, 11:02 AM

|

#84

|

|

Almost There

Join Date: Sep 2013

Location: Mount Victory, OH

Posts: 85

|

I wonder if there is some PEX that would withstand the high temps of coolant and would last longer than 3-4 yrs and be cheaper too. How about black iron or galvanized pipe if you plan to run inside the bus but under your finished floor.

|

|

|

09-14-2016, 11:41 AM

09-14-2016, 11:41 AM

|

#85

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,830

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

PEX for heating is max at 200 degrees so i wouldnt use it for coolant loops.. if you were to overheat your bus it could run up to 230 or higher...

theres regular copper pipe.. or perhaps flexible refrigerant copper tubing would work..

I seriously doubt that most of the rubber heater lines in these busses have been replaced every 3-4 years.. and if kept in an indoor environment where they arent open to the elements or excessive engine heat, UV, salt, Oil, etc they will last quite a bit longer than 3-4 years

-Christopher

|

|

|

09-14-2016, 02:09 PM

09-14-2016, 02:09 PM

|

#86

|

|

Traveling

Join Date: Aug 2016

Posts: 198

|

Yep, heater hoses *can* last for decades, as long as nothing is rubbing on them. If there is something rubbing on them, it might be only hours.

|

|

|

09-17-2016, 10:38 PM

09-17-2016, 10:38 PM

|

#87

|

|

Skoolie

Join Date: Jun 2016

Location: Texas

Posts: 160

Year: 1997

Chassis: Saf-T-Liner MVP ER

Engine: Cummins 5.9L Diesel Engine

Rated Cap: 83

|

|

|

|

09-17-2016, 11:12 PM

09-17-2016, 11:12 PM

|

#88

|

|

Bus Nut

Join Date: Oct 2011

Location: Snowflake, Arizona

Posts: 343

Year: 1996

Coachwork: Blue Bird

Chassis: All American Rear Engine

Engine: C-8.3-300 Cummins MD3060

Rated Cap: 40 Prisoners

|

The yellow wrecking bar is at least a foot or possibly two feet

short for pulling floor nails but it can be accomplished with the

smaller tool if you hammer the nails side to side to slightly open

the floor holes before pulling the nail.

|

|

|

09-18-2016, 06:47 AM

09-18-2016, 06:47 AM

|

#89

|

|

Bus Nut

Join Date: Mar 2015

Location: hills of sw virginia

Posts: 889

Year: 1996

Chassis: thomas

Engine: 8.3 cummins

Rated Cap: 11 window

|

check ebay for heater hose, i got 100 feet of 3/4 for 90 bucks delivered.it had 1" but with the pump its big enough. i ran my hose under also. great job on your build

|

|

|

09-18-2016, 07:10 AM

09-18-2016, 07:10 AM

|

#90

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,830

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

you want to use 1" for your main heater feed lines, then most smaller heaters that are purchased will use 5/8.. I boight some 1" to 5/8" adapters.. even with the pump you will find you need more heat than you think you do..

1" heater line is sold at almost every NAPA store.. I bought a bunch of it as I replaced alot of heater line in my bus...

-Christopher

|

|

|

09-18-2016, 08:02 AM

09-18-2016, 08:02 AM

|

#91

|

|

Bus Nut

Join Date: Feb 2015

Location: Houston, Tx.

Posts: 403

Year: 1999

Coachwork: AmTran

Chassis: International

Engine: DT466E

Rated Cap: 84

|

Quote:

Originally Posted by Justin McCormick

Awesome, thanks! What kind of heaters are they?

**update** I just looked at the pictures of your bus on your build thread. They look like they might be in better shape then mine. I am certainly interested. If you will stash them for me I can drive out and when I pick them up I can lend a hand on your bus for an afternoon.

|

Sorry for the delayed response Justin, I just now saw this. I'm not sure who the manufacture is but I'll take pics next Saturday when I go work on it again. The are in great shape as the top fins has a protective cover over it. I'll keep them in storage for you as long as you need.

|

|

|

09-18-2016, 08:19 AM

09-18-2016, 08:19 AM

|

#92

|

|

Bus Nut

Join Date: Feb 2015

Location: Houston, Tx.

Posts: 403

Year: 1999

Coachwork: AmTran

Chassis: International

Engine: DT466E

Rated Cap: 84

|

Great job pulling up your floors. You're lucky yours are nailed down. Mine are all screwed down with 1/2" wood screws, which are mostly frozen in place so I have to cut around each screw just to get my plywood out, and then angle grind the screw off at floor level. Major pain in the arse.

|

|

|

09-18-2016, 08:40 AM

09-18-2016, 08:40 AM

|

#93

|

|

Skoolie

Join Date: Jun 2016

Location: Texas

Posts: 160

Year: 1997

Chassis: Saf-T-Liner MVP ER

Engine: Cummins 5.9L Diesel Engine

Rated Cap: 83

|

Quote:

Originally Posted by FlyboyHPD

Great job pulling up your floors. You're lucky yours are nailed down. Mine are all screwed down with 1/2" wood screws, which are mostly frozen in place so I have to cut around each screw just to get my plywood out, and then angle grind the screw off at floor level. Major pain in the arse.

|

Dang!!! That sucks. That probably slows things down. Thanks for holding on to the heaters, I am still working out placement, but if I am going to bother replacing the heater hose I might as well throw a couple into the floor plan.

Quote:

Originally Posted by superdave

check ebay for heater hose, i got 100 feet of 3/4 for 90 bucks delivered.it had 1" but with the pump its big enough. i ran my hose under also. great job on your build

|

Thanks! ebay is a good idea. 90 bucks is a great deal.

|

|

|

09-18-2016, 11:54 AM

09-18-2016, 11:54 AM

|

#94

|

|

Bus Nut

Join Date: Mar 2015

Location: hills of sw virginia

Posts: 889

Year: 1996

Chassis: thomas

Engine: 8.3 cummins

Rated Cap: 11 window

|

Quote:

Originally Posted by cadillackid

you want to use 1" for your main heater feed lines, then most smaller heaters that are purchased will use 5/8.. I boight some 1" to 5/8" adapters.. even with the pump you will find you need more heat than you think you do..

1" heater line is sold at almost every NAPA store.. I bought a bunch of it as I replaced alot of heater line in my bus...

-Christopher

|

i disagree, i went thru a snowstorm in west virginia last feb in my 32' rear engine bus on my way to IL. with no problems, hoses were screaming hot. as far as napa, you will pay 3 times what you would pay on line for good quality hose. 3/4 is the way to go, imo.

|

|

|

09-18-2016, 01:32 PM

09-18-2016, 01:32 PM

|

#95

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,830

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

3/4 or 1 inch all depends on how many heaters you are driving with it... screaming hot feed hoses mean nothing... heater core and air temperature means all... i want to be WARM!! so I have a bunch of heaters in my bus... havent had it through the winter yet.. but if Im out in 0 degree weather i want to be inside with my coat on a seat somewhere not on me..

-Christopher

|

|

|

09-18-2016, 02:34 PM

09-18-2016, 02:34 PM

|

#96

|

|

Bus Nut

Join Date: Feb 2015

Location: North carolina

Posts: 651

Year: 1986

Coachwork: Thomas

Chassis: Ford

Engine: Detroit 8.2

Rated Cap: 60 bodies

|

I would like to comment on the heater hose subject and I do have opinions on sizing but to each his own?

My comment will be on the type of tubing,piping that is chosen?

For anything hot water the tubing piping will,is going to flex and move!

As the water and piping heat up it will expand and as it cools down it will contract.

Any point of contact with anything eventually will rub through and the type of piping material used will decide how long until it happens.

I do a lot of high temp. Hot water work and have even sch.80 steel pipe move concrete (underground steam 220 minimum) (close to the same temp. As a bus starting to overheat) because of no room to expand. In my world we add expansion loops or joints.

Running heater hoses underside is a good idea cause they are always replaceable/maintaneable but an extra foot in a loop just underside before your heater connection to me is a good idea ?

For the ones interested in the radiant heated flooring idea in a skoolie I can only give my idea if I went that direction? (I have done several radiant flooring in a commercial construction world where all is buried in concrete and can't move) so immediately after leaving the concrete slab I have learned to give the piping room to expand and contract.

Not trying to scare anyone but I could reccomend using 2" foam board, carve your pipe size channels into the top inch? Of your foam board, lay you tubing with no joint's if possible, a 1/4" underlayment or foam board then finished flooring and before you cover your tubing stretch a tape and take a picture of your tubing layout for when you need to screw,anchor,drill a hole later.

|

|

|

09-18-2016, 04:54 PM

09-18-2016, 04:54 PM

|

#97

|

|

Bus Nut

Join Date: Mar 2015

Location: hills of sw virginia

Posts: 889

Year: 1996

Chassis: thomas

Engine: 8.3 cummins

Rated Cap: 11 window

|

Quote:

Originally Posted by Jolly Roger

I would like to comment on the heater hose subject and I do have opinions on sizing but to each his own?

My comment will be on the type of tubing,piping that is chosen?

For anything hot water the tubing piping will,is going to flex and move!

As the water and piping heat up it will expand and as it cools down it will contract.

Any point of contact with anything eventually will rub through and the type of piping material used will decide how long until it happens.

I do a lot of high temp. Hot water work and have even sch.80 steel pipe move concrete (underground steam 220 minimum) (close to the same temp. As a bus starting to overheat) because of no room to expand. In my world we add expansion loops or joints.

Running heater hoses underside is a good idea cause they are always replaceable/maintaneable but an extra foot in a loop just underside before your heater connection to me is a good idea ?

For the ones interested in the radiant heated flooring idea in a skoolie I can only give my idea if I went that direction? (I have done several radiant flooring in a commercial construction world where all is buried in concrete and can't move) so immediately after leaving the concrete slab I have learned to give the piping room to expand and contract.

Not trying to scare anyone but I could reccomend using 2" foam board, carve your pipe size channels into the top inch? Of your foam board, lay you tubing with no joint's if possible, a 1/4" underlayment or foam board then finished flooring and before you cover your tubing stretch a tape and take a picture of your tubing layout for when you need to screw,anchor,drill a hole later.

|

for floor heating foam board is a bad idea, it wont pul the heat out of the tube. read this http://www.warmboard.com/warmboard-r

|

|

|

09-19-2016, 09:43 AM

09-19-2016, 09:43 AM

|

#98

|

|

Skoolie

Join Date: Jun 2016

Location: Texas

Posts: 160

Year: 1997

Chassis: Saf-T-Liner MVP ER

Engine: Cummins 5.9L Diesel Engine

Rated Cap: 83

|

Latest video, mostly of tearing up the floor.

|

|

|

09-19-2016, 11:31 AM

09-19-2016, 11:31 AM

|

#99

|

|

Bus Crazy

Join Date: Dec 2014

Location: Dowdy Lakes, Colorado

Posts: 1,444

Year: 1989

Coachwork: Thomas

Chassis: Saf-T-Liner ER

Engine: 3208 CAT/MT643 tranny

Rated Cap: 87

|

Quote:

Originally Posted by Justin McCormick

Latest video, mostly of tearing up the floor.

|

@ 4:39 you have my empathies!!!!!!

BTW, you remind me of my favorite college roommate, looks, mannerisms, body language, the whole nine yards!

At least your floors came up without too much of a fight. Mine took me five weeks of fighting before I was successful..........

__________________

Firearms stand next in importance to the Constitution itself. They are the American people’s liberty teeth and keystone under independence. — George Washington

|

|

|

09-20-2016, 04:08 PM

09-20-2016, 04:08 PM

|

#100

|

|

Skoolie

Join Date: Jun 2016

Location: Texas

Posts: 160

Year: 1997

Chassis: Saf-T-Liner MVP ER

Engine: Cummins 5.9L Diesel Engine

Rated Cap: 83

|

I meant to post this picture sooner, but this was from the end of the day Sunday, after getting all the wood up. I was relived and happy to see it was very clean metal.

I still have a piece of wood under the drivers seat, and the front dash. I have a feeling that its going to be tricky getting out.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|