|

|

01-30-2017, 09:22 AM

01-30-2017, 09:22 AM

|

#21

|

|

Skoolie

Join Date: Mar 2016

Location: chicago, il

Posts: 220

Year: 2003

Chassis: IC CE

Engine: T444

|

Quote:

Originally Posted by Carytowncat

Also my chimney goes right out the window like yours. I couldnt bring myself to cut a hole in the bus roof, especially before i have tested the wood stove for at least a year and KNOW im not going to move it

|

i have a huge stove in comparison to yours. but have the same sentiment. i also have a buddy heater as backup.

|

|

|

01-30-2017, 09:24 AM

01-30-2017, 09:24 AM

|

#22

|

|

Skoolie

Join Date: Mar 2016

Location: chicago, il

Posts: 220

Year: 2003

Chassis: IC CE

Engine: T444

|

Quote:

Originally Posted by EastCoastCB

Op- was it you that asked about this a week or two ago?

There was a thread about this. I found it a bit funny that no one but me was saying to run the chimney straight up.

|

i cant remember but its possible? also do i not need the protective nook for my stove?

|

|

|

01-30-2017, 09:26 AM

01-30-2017, 09:26 AM

|

#23

|

|

Skoolie

Join Date: Mar 2016

Location: chicago, il

Posts: 220

Year: 2003

Chassis: IC CE

Engine: T444

|

Quote:

Originally Posted by cadillackid

thats why I suggest a power vent... they are great for short run or hotizontal chimneys... it creates an artificial draft.. the good ones are variable speed sp they dont create too much of a draft and burn up all your wood.

you can also use a slight draft inducer if you have a sealed stove. a slight positive pressure into the air intake of a stove can induce a draft.. that air amount can be varied for the amount of burn you want. you need a sealed stove for that concept to work, but you also wont get any backdrafting as you air intake is sealed except for the inducer inlet.

-Christopher

|

ill look into the power vent, have any links or stores you suggest?

|

|

|

01-30-2017, 09:35 AM

01-30-2017, 09:35 AM

|

#24

|

|

Skoolie

Join Date: Nov 2016

Location: Alberta

Posts: 134

Year: 1996

Coachwork: Thomas 72 passenger

Chassis: International 3800

Engine: 230HP DT466 engine MD3060 transmission

|

Quote:

Originally Posted by Carytowncat

Also my chimney goes right out the window like yours. I couldnt bring myself to cut a hole in the bus roof, especially before i have tested the wood stove for at least a year and KNOW im not going to move it

|

Never use galvanized steel as a wood stove chimney. All galvanized stov  e pipes are coated with zinc which, when heated to 1,652 degrees, vaporizes, emitting toxic zinc fumes.

|

|

|

01-30-2017, 10:01 AM

01-30-2017, 10:01 AM

|

#25

|

|

Bus Nut

Join Date: Oct 2016

Location: Pensacola and Crystal River, FL

Posts: 647

Year: 1998

Coachwork: AmTran International

Chassis: 3800

Engine: Navistar 7.6L

|

That galvanized ducting looks like maybe just a sleeve over the actual stove pipe.

With air space in between?

But yea, zinc fumes are BAD. The galvanizing will start to run off at 820 to 860 degrees.

For O.P.

you could maybe use a tee inside instead of the flex in order to fit the turn into your plan. Cap off and seal the un-used end.

|

|

|

01-30-2017, 10:11 AM

01-30-2017, 10:11 AM

|

#26

|

|

Bus Nut

Join Date: Oct 2016

Location: Pensacola and Crystal River, FL

Posts: 647

Year: 1998

Coachwork: AmTran International

Chassis: 3800

Engine: Navistar 7.6L

|

Quote:

Originally Posted by Azuleslight

ill look into the power vent, have any links or stores you suggest?

|

If your handy you could fab up your own draft inducer by adding a tiny blower and a venturi pipe inside your stack.

They also make a venture inducing cap, some look like this.

Not sure if they are effective when mounted with inlet horizontal.

|

|

|

01-30-2017, 10:46 AM

01-30-2017, 10:46 AM

|

#27

|

|

Bus Nut

Join Date: Mar 2016

Location: near Christiansburg VA

Posts: 692

Coachwork: Thomas

Chassis: Freightliner

Engine: Cummins 5.9

Rated Cap: 44 or 66? 11 rows

|

Quote:

Originally Posted by DoubleO7

... zinc fumes are BAD. The galvanizing will start to run off at 820 to 860 degrees. ....

|

As in, "deadly". Lost a blacksmith friend: Zinc Metal Fume Fever : A Case Study : Blacksmithing How-to on anvilfire iForge

|

|

|

01-30-2017, 08:55 PM

01-30-2017, 08:55 PM

|

#28

|

|

Skoolie

Join Date: Mar 2016

Location: chicago, il

Posts: 220

Year: 2003

Chassis: IC CE

Engine: T444

|

so i added a dampener to the base connector for now to stop blow back. i apparently have to order the double wall 90. i plan to check another menards to see if they have it. then im going to cap it for now and wait yo add the 3 foot extension as suggested.

|

|

|

01-30-2017, 10:47 PM

01-30-2017, 10:47 PM

|

#29

|

|

Bus Nut

Join Date: May 2016

Location: Richmond Virginia

Posts: 932

Year: 1984

Engine: 366 Big block Chevy! :) w/ Stick shift

|

Thanks for lookin out for me guys but yes those are double wall and certainly never reach that high of a temp.

It is a major chimney pipe manufacturer air-jet.

However... for safety's sake i may grab a temp gun and take a reading, better safe than sorry and just hecause they are a mJor manufacturer doesn't mean they can be trusted with my lungs.

|

|

|

01-31-2017, 09:24 AM

01-31-2017, 09:24 AM

|

#30

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

I have a decent time invested in chimney installation and research, so I'll throw my 5 cents into the ring (Canada no longer has pennies, you see).

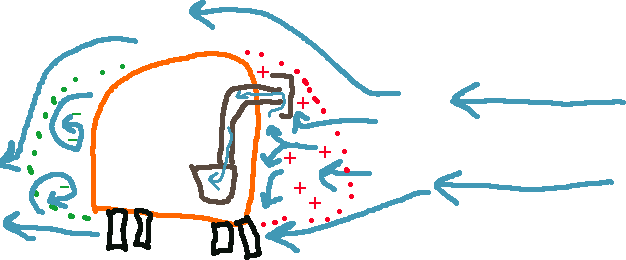

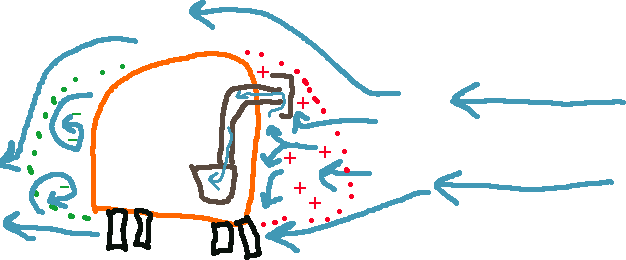

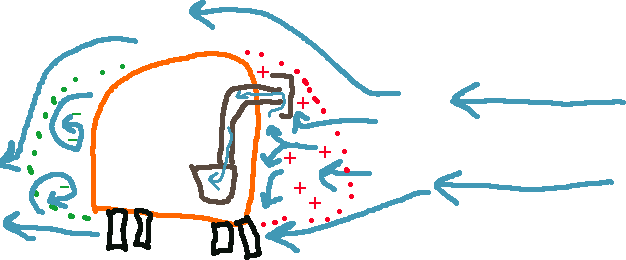

Most chimney draft issues are due to bends, an outdoor installation, or not enough chimney height. Of all of these issues an outdoor installation is the scariest. With the chimney completely outside it's possible for it to cool enough to overpower a lightly burning fire, which can dump huge amounts of carbon monoxide into the living space.

I don't expect you'll ever get a good draft with such a short stack employing a 90° elbow. Elbows considerable reduce draft no matter the chimney they're installed on. They also encourage creosote build up.

Second, a horizontal termination is inevitably going to cause back draft when the wind is right (wrong?). Heck, on a windy day it could potentially over power even a chimney draft blower. The problem has to do with wind direction and pressure.

When the wind is blowing towards the chimney cap side of the bus it will create a high pressure zone that will easily over power the chimney's draft and thus send air down the chimney. There is no natural draft chimney cap that can prevent this. They are meant to be installed vertically and above the roof line.

Contrariwise, when the wind is blowing towards the side of the bus without the chimney cap you will get a negative pressure on the chimney side which will suck the air out the chimney.

When the wind is blowing from the front or back of the bus you'll have neutral pressure on the sides.

Here's a sweet picture some kindergartener drew up for me (jk.. I drew it. how embarrassing):

The only solution that will work 98% of the time is a vertically mounted chimney cap that is above the roof line. I say 98% of the time because the wind can come down at you vertically if you're parked next to a structure with just the right shape.

While not ideal, a short term solution would be to add another elbow and bring the chimney termination above the roof line. You are likely to still get smoke rolling out the door when loading, but at least it shouldn't backdraft into the living space when the door is closed.

Also, it seems that single stage wood stoves require less chimney draft to operate than wood stoves that are built with a secondary burner. Secondary burners usually have a couple internal 90° corners for the smoke to travel while it gets re-burned. They result in a cleaner burn and more heat per weight of wood, but require a good chimney installation. Do you know which kind you have?

I know a lot of this has already been said by previous posters, but puking up a complete idea seemed easier than replying to a handful of quotes

Good luck!

|

|

|

01-31-2017, 10:57 PM

01-31-2017, 10:57 PM

|

#31

|

|

Mini-Skoolie

Join Date: Jan 2015

Location: Oakland, Ca

Posts: 58

Chassis: Crown Supercoach

Engine: Detroit Diesel 6-71 Mid-ship

Rated Cap: 78

|

Your stovepipe is far too short for the "chimney effect" to work.

https://en.wikipedia.org/wiki/Stack_effect

Most stove manufacturers require 12' of 6" pipe from the collar on the top of the stove to the top of the chimney. I'm not a stickler for "code" or anything but if you use that as a rough guide, you can see you're way too short.

That flexible corrugated stuff isn't aluminum is it? If so, you need to change that too. Aluminum can not handle the high temperature wood smoke.

|

|

|

01-31-2017, 11:21 PM

01-31-2017, 11:21 PM

|

#32

|

|

Bus Nut

Join Date: May 2016

Location: Richmond Virginia

Posts: 932

Year: 1984

Engine: 366 Big block Chevy! :) w/ Stick shift

|

Quote:

Originally Posted by jazty

I have a decent time invested in chimney installation and research, so I'll throw my 5 cents into the ring (Canada no longer has pennies, you see).

Most chimney draft issues are due to bends, an outdoor installation, or not enough chimney height. Of all of these issues an outdoor installation is the scariest. With the chimney completely outside it's possible for it to cool enough to overpower a lightly burning fire, which can dump huge amounts of carbon monoxide into the living space.

I don't expect you'll ever get a good draft with such a short stack employing a 90° elbow. Elbows considerable reduce draft no matter the chimney they're installed on. They also encourage creosote build up.

Second, a horizontal termination is inevitably going to cause back draft when the wind is right (wrong?). Heck, on a windy day it could potentially over power even a chimney draft blower. The problem has to do with wind direction and pressure.

When the wind is blowing towards the chimney cap side of the bus it will create a high pressure zone that will easily over power the chimney's draft and thus send air down the chimney. There is no natural draft chimney cap that can prevent this. They are meant to be installed vertically and above the roof line.

Contrariwise, when the wind is blowing towards the side of the bus without the chimney cap you will get a negative pressure on the chimney side which will suck the air out the chimney.

When the wind is blowing from the front or back of the bus you'll have neutral pressure on the sides.

Here's a sweet picture some kindergartener drew up for me (jk.. I drew it. how embarrassing):

The only solution that will work 98% of the time is a vertically mounted chimney cap that is above the roof line. I say 98% of the time because the wind can come down at you vertically if you're parked next to a structure with just the right shape.

While not ideal, a short term solution would be to add another elbow and bring the chimney termination above the roof line. You are likely to still get smoke rolling out the door when loading, but at least it shouldn't backdraft into the living space when the door is closed.

Also, it seems that single stage wood stoves require less chimney draft to operate than wood stoves that are built with a secondary burner. Secondary burners usually have a couple internal 90° corners for the smoke to travel while it gets re-burned. They result in a cleaner burn and more heat per weight of wood, but require a good chimney installation. Do you know which kind you have?

I know a lot of this has already been said by previous posters, but puking up a complete idea seemed easier than replying to a handful of quotes

Good luck! |

Thank you for this info, i had not considered the cooling effect of the outside chimney.

hmmm maybe time to get out the sawzall. lol

|

|

|

01-31-2017, 11:29 PM

01-31-2017, 11:29 PM

|

#33

|

|

Bus Crazy

Join Date: May 2015

Location: Oklahoma aka "God's blind spot"

Posts: 2,446

Year: 1989

Coachwork: 1853FC International/Navistar

Chassis: 35' Retired Air Force Ambulance

Engine: DT466, MT643

Rated Cap: 6 souls and a driver

|

Quote:

Originally Posted by jazty

I have a decent time invested in chimney installation and research, so I'll throw my 5 cents into the ring (Canada no longer has pennies, you see).

Most chimney draft issues are due to bends, an outdoor installation, or not enough chimney height. Of all of these issues an outdoor installation is the scariest. With the chimney completely outside it's possible for it to cool enough to overpower a lightly burning fire, which can dump huge amounts of carbon monoxide into the living space.

I don't expect you'll ever get a good draft with such a short stack employing a 90° elbow. Elbows considerable reduce draft no matter the chimney they're installed on. They also encourage creosote build up.

Second, a horizontal termination is inevitably going to cause back draft when the wind is right (wrong?). Heck, on a windy day it could potentially over power even a chimney draft blower. The problem has to do with wind direction and pressure.

When the wind is blowing towards the chimney cap side of the bus it will create a high pressure zone that will easily over power the chimney's draft and thus send air down the chimney. There is no natural draft chimney cap that can prevent this. They are meant to be installed vertically and above the roof line.

Contrariwise, when the wind is blowing towards the side of the bus without the chimney cap you will get a negative pressure on the chimney side which will suck the air out the chimney.

When the wind is blowing from the front or back of the bus you'll have neutral pressure on the sides.

Here's a sweet picture some kindergartener drew up for me (jk.. I drew it. how embarrassing):

The only solution that will work 98% of the time is a vertically mounted chimney cap that is above the roof line. I say 98% of the time because the wind can come down at you vertically if you're parked next to a structure with just the right shape.

While not ideal, a short term solution would be to add another elbow and bring the chimney termination above the roof line. You are likely to still get smoke rolling out the door when loading, but at least it shouldn't backdraft into the living space when the door is closed.

Also, it seems that single stage wood stoves require less chimney draft to operate than wood stoves that are built with a secondary burner. Secondary burners usually have a couple internal 90° corners for the smoke to travel while it gets re-burned. They result in a cleaner burn and more heat per weight of wood, but require a good chimney installation. Do you know which kind you have?

I know a lot of this has already been said by previous posters, but puking up a complete idea seemed easier than replying to a handful of quotes

Good luck! |

That's pretty much what I was saying, right?

I've burnt enough bbq wood to know that if you're seeing smoke, you're not burning efficiently enough. The smoke is in the cooking chamber, but once it's drafted out the stack and mixed with enough air... You'll barely see smoke.

I know it's apples & oranges, but I feel the principles are the same.

__________________

I once complained I had no shoes....

Until I met a man with no feet

|

|

|

02-01-2017, 09:03 AM

02-01-2017, 09:03 AM

|

#34

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by Carytowncat

Thank you for this info, i had not considered the cooling effect of the outside chimney.

hmmm maybe time to get out the sawzall. lol

|

When I mentioned outdoor chimneys I was think of these two styles installed on tall houses:

You want to keep as much of the chimney inside as possible and exit through the roof. You get two benefits out of it. It'll add a bit more heat to the living space and the heat in the living space will keep the stack from cooling down too a dangerously low temperature. With the little stacks that school buses are likely to have installed you won't see drastic chimney cooling of the outdoor portion. I mentioned it previously to complete the thought, but its mostly an issue for houses where the home owner is looking for short cuts...

|

|

|

02-01-2017, 10:46 AM

02-01-2017, 10:46 AM

|

#35

|

|

Bus Geek

Join Date: May 2009

Location: Columbus Ohio

Posts: 18,835

Year: 1991

Coachwork: Carpenter

Chassis: International 3800

Engine: DTA360 / MT643

Rated Cap: 7 Row Handicap

|

the aluminum should handle the temperature of a "NORMAL" fire.. but when the draw is slow the stack temperature rises... and *IF* god forbid you should have a chimney fire or even a small amount of creosote burn off it WILL MELT!..

the other issue with flexible pipe is that the ridges in it

1. slow down and create turbulence in the exhaust-flow. whuch makes the draw to outside harder for it to maintain.

2. the inside ridges are a Magnet for creosote to stick and form and is also very tough to clean effectively... see above about a chimney fire..

-Christopher

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|