|

|

10-23-2017, 11:47 PM

10-23-2017, 11:47 PM

|

#21

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by Iceni John

I think these ideas would confuse even Rube Goldberg! Where's KISS, or at least the notion of engineering elegance through what Robert Pirsig called "lessness"?

I hinge my panels from the central walkway between my two roof hatches, and through the front hatch I can easily climb up onto the walkway to clean panels when needed. (I put two water quick-connect outlets up there, so to wash down the panels needs only a washdown brush and short curly hose. No dragging hoses or heavy buckets of water up there for me.) Each panel sits in its own support frame made from 6063 angle, so to change out a panel would take only a few minutes. When the panels are down against the roof for travel they are at 21 degrees below horizontal, but each one can be raised to level, 21 degrees up (for summer), 33 degrees up (for spring or fall), or 45 degrees up (for winter). This means that in summer one side of panels is 21 degrees down, and the opposite side of panels is 21 degrees up. Guess what the ideal summer angle for panels in SoCal is? When the sun is lower in the sky, I raise the far-side panels higher, but the near-side is always at 21 degrees down. It's not quite as good as having all my panels able to be fully raised, but any loss of solar harvest will be inconsequential, especially that I have over 2000 watts of them anyway! (I think that most of the year I'll have far more potential power-production than I'll need, but for overcast short winter days you really can't have too much PV.)

The actual way I raise the panels is with simple home-made stainless-steel telescoping struts with snap buttons. Each strut's top end is hinged and pivots onto the panel, and the bottom end pivots and slides in a length of T-track that is hinged to a longitudinal 6061 angle rail against the roof. This way, each strut telescopes, pivots, slides and hinges, ensuring that only compressive loads are seen. When down against the roof for travel each panel is secured by two clamps onto the 6061 angle, absolutely preventing any movement whatsoever. To raise a panel only needs me to release the clamps, then just raise it as far as needed; to lower it I just push in the snap buttons and down it comes. Easy! And yes, I get up on a step ladder - what's wrong with that? Everything is made from 18/8 stainless-steel and 6061 or 6063 aluminum for all-weather dependability and long-term reliability.

Each panel's MC4 connectors mate with its own 10AWG feed-in cable that runs inside aluminum conduit, and each side of four panels feed into a combiner box under the walkway from where the individually-fused and paralleled outputs are sent by 4AWG welding cables inside the roof ribs down to the charge controllers' 50A input breakers. Each side of panels has its own Morningstar TS-MPPT-60 charge controller that charges its own bank of (eventually) four golfcart or L-16 batteries through some 80A breakers. In effect I have two completely separate and independent systems running in parallel, and each battery bank has a 250A Schottky output diode to prevent back-feeding to the other before they combine at the DC load center that powers the Magnum MS2000 inverter and the DC loads. This way I have complete redundancy - nothing could ever deprive me of power! Each bank of batteries need not even be the same type or age - I can use whatever I buy at the time, and replace half the batteries at one time to prevent having all my batteries dying at the same time. All the batteries are on pull-out trays of my own design, just like the start batteries also have, and the charge controllers and inverter(s) are also on swing-out mounts for easy access. The house batteries can also be connected to the start batteries for cold-weather boosting, using a pair of Blue Sea high-capacity rotary switches for their Pos and Neg 4/0 interconnection cables.

Yes, it's a lot of work to do it this way, but in the long run it will be more reliable and effective than other systems I've seen. It's still a fundamentally simple system, with everything designed for easy access and serviceability.

John

|

I feel so foolish now for posting my idea now that I've seen the easier way. That is the beauty of this site, we can all learn from those that have done before us. I bet Grainger stocks all those materials, except the step ladder, but I can use a 5-gallon bucket for that part.

Thanks-

|

|

|

10-24-2017, 12:20 AM

10-24-2017, 12:20 AM

|

#22

|

|

Almost There

Join Date: Sep 2017

Location: Tracy, CA atm

Posts: 74

Year: 1991

Coachwork: Crown Supercoach Series II

Engine: Detroit 6V92TAC

|

Quote:

Originally Posted by Rusty

I feel so foolish now for posting my idea now that I've seen the easier way. That is the beauty of this site, we can all learn from those that have done before us. I bet Grainger stocks all those materials, except the step ladder, but I can use a 5-gallon bucket for that part.

Thanks-  |

I still like the single actuator lifting multiple panels but I can see using the e-exit to it's advantage. It's good to talk it out this way. I have gained from the different ideas. If you didn't post the so-called foolish idea you might not have sorted it out before building something. Same here. I do feel the need to give up hopes on being the next Da Vinci and it sort of ruins my delusions of grandeur but I'll get over it. Using the e-exit more often has good potential though. I mean, we have it so might as well use it. Calling out for super complicated ladder designs! I'm thinking carbon fiber...hmmm. But seriously, that is probably next. *prepares to fingerpaint the new masterpiece*

|

|

|

10-24-2017, 12:29 AM

10-24-2017, 12:29 AM

|

#23

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by yello

I still like the single actuator lifting multiple panels but I can see using the e-exit to it's advantage. It's good to talk it out this way. I have gained from the different ideas. If you didn't post the so-called foolish idea you might not have sorted it out before building something.

|

I still like the cantilever pneumatic system- just think how cool it's be to be able to pull a valve and dump all that snow on somebody?

My new design:

teeter-clipart-8.jpg

|

|

|

10-24-2017, 12:45 AM

10-24-2017, 12:45 AM

|

#24

|

|

Almost There

Join Date: Sep 2017

Location: Tracy, CA atm

Posts: 74

Year: 1991

Coachwork: Crown Supercoach Series II

Engine: Detroit 6V92TAC

|

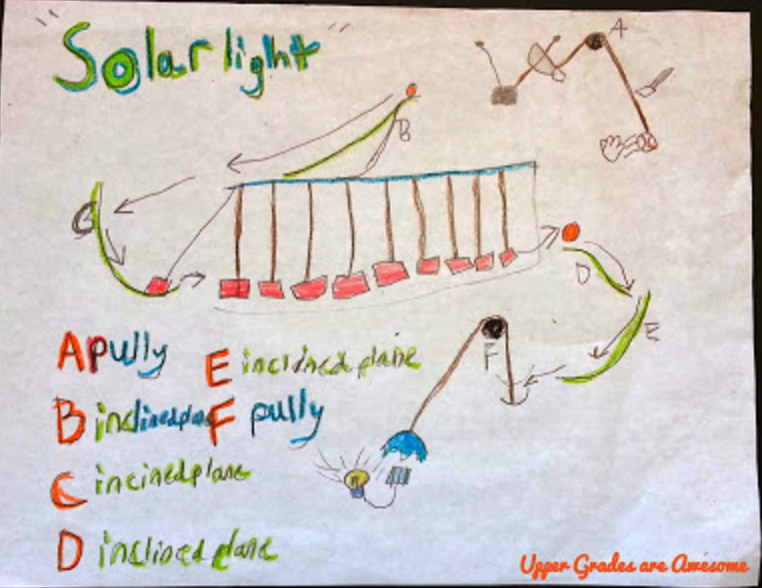

Found out that someone has been stealing my ideas...

|

|

|

11-14-2017, 11:32 AM

11-14-2017, 11:32 AM

|

#25

|

|

Skoolie

Join Date: Aug 2017

Location: Phoenix, AZ

Posts: 228

Year: 1997

Coachwork: Blue Bird

Chassis: AARE 3903

Engine: Cummins 8.3L 12v

Rated Cap: 78

|

The cantilever design is very slick, but I would be hesitant to use anything on a bus that does not support the panels on both sides when driving. I had to do all the wind load calculations for our home install to make the city inspector happy, and it's pretty crazy the kind of forces that can be created. And not always in the directions you think. For each 8 panel subarray the loads up or down could be many thousands of pounds, which would create some incredible forces at the attach points. Even with dual support rails moments were in the 10s of thousands of inch pounds.

|

|

|

11-14-2017, 11:52 AM

11-14-2017, 11:52 AM

|

#26

|

|

Traveling

Join Date: Nov 2015

Location: Midwest

Posts: 2,573

Year: 2003

Coachwork: BlueBird

Chassis: TC2000

Engine: 5.9L Cummins

Rated Cap: '00

|

Quote:

Originally Posted by miscrms

Even with dual support rails moments were in the 10s of thousands of inch pounds.

|

Luckily, the price of solar panels has come down to the point where it is financially feasible to just order new panels to replace those as they blow-off down the highway.

|

|

|

11-14-2017, 02:49 PM

11-14-2017, 02:49 PM

|

#27

|

|

Skoolie

Join Date: Aug 2017

Location: Phoenix, AZ

Posts: 228

Year: 1997

Coachwork: Blue Bird

Chassis: AARE 3903

Engine: Cummins 8.3L 12v

Rated Cap: 78

|

LOL, I suppose thats true ;)

|

|

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|