|

|

11-04-2016, 02:20 PM

11-04-2016, 02:20 PM

|

#21

|

|

Bus Nut

Join Date: Sep 2016

Location: Darrington, Wa.

Posts: 304

Year: 1994

Coachwork: Genesis/Am-Tran Tall Roof

Chassis: International, 643 transmission

Engine: DT 466ci 250hp, International

Rated Cap: 86 screaming Monsters

|

I was just looking at my floor thinking of the shop space in the rear. I don't want anything I can spill say oil on and it soak in. I like the idea of just treating it like its a cement garage floor and laying down some anti slip paint. Then I can mop it wipe it down or just clean it and repaint later.

In the lving quarters side i have yet to here of this story of foam crushing. What foam are we speaking of and what PSI PSF. I was planning on spray foam on the walls roof and the board stuff installed just Like the mudda earth video.

I'm not planning on going any where cold at all. So the shop area I'm not worried about all that much. The roof and walls were going to be for the condensation and air conditioning.

Am I doing this wrong? Its like we need a thread added for cold climate and warm climate.

|

|

|

11-04-2016, 03:23 PM

11-04-2016, 03:23 PM

|

#22

|

|

Bus Nut

Join Date: Jan 2015

Location: Kansas

Posts: 492

Year: 2000

Chassis: International 3800

Engine: T444E

Rated Cap: Your mom +1

|

Quote:

Originally Posted by Geo Jeff

I'm not planning on going any where cold at all. So the shop area I'm not worried about all that much. The roof and walls were going to be for the condensation and air conditioning.

Am I doing this wrong? Its like we need a thread added for cold climate and warm climate.

|

Insulation isn't just for cold climates... You're gonna need it to keep heat out and air conditioning in...

|

|

|

11-04-2016, 05:07 PM

11-04-2016, 05:07 PM

|

#23

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

Quote:

Originally Posted by Geo Jeff

I was just looking at my floor thinking of the shop space in the rear. I don't want anything I can spill say oil on and it soak in. I like the idea of just treating it like its a cement garage floor and laying down some anti slip paint. Then I can mop it wipe it down or just clean it and repaint later.

In the lving quarters side i have yet to here of this story of foam crushing. What foam are we speaking of and what PSI PSF. I was planning on spray foam on the walls roof and the board stuff installed just Like the mudda earth video.

I'm not planning on going any where cold at all. So the shop area I'm not worried about all that much. The roof and walls were going to be for the condensation and air conditioning.

Am I doing this wrong? Its like we need a thread added for cold climate and warm climate.

|

A bare garage is a good idea though I will probably insulate mine to keep my batteries a little toastier. As for the foam crushing or not ... it's probably fine in most cases but there's a reason professional contractors frame a floor. I just don't understand why people are reinventing the wheel. Framing a floor is not a new concept. That insulation is really not designed to take the weight of a counter/fridge/stove/whatever else you're piling on it. Rigid foam is hard to squish but as you compress it you lose insulation value. Same goes for fiberglass -- it's rated to what it says only assuming you leave an appropriate air gap, and only assuming you are framing it in 2x4's. If you frame it in metal you get roughly half the R value. How do you think that'll look after years of use? I know there are differing opinions on the subject but why skip such an easy step? It's a shortcut. I don't see the advantage.

__________________

Roads? Where we're going, we don't need ... roads.

|

|

|

11-04-2016, 05:37 PM

11-04-2016, 05:37 PM

|

#24

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by warewolff

As for the foam crushing or not ... it's probably fine in most cases but there's a reason professional contractors frame a floor. I just don't understand why people are reinventing the wheel. Framing a floor is not a new concept. That insulation is really not designed to take the weight of a counter/fridge/stove/whatever else you're piling on it. Rigid foam is hard to squish but as you compress it you lose insulation value.

|

You gotta believe me on this: with a proper subfloor of 5/8" or 3/4" plywood or OSB you will not squash XPS foam. Try as you might, it will not compress. In fact, it's common practice these days to lay XPS rigid foam (of the proper density) down before pouring concrete for basements, parking garages, industrial complexes you name it. All you need to keep XPS from crushing is the proper sandwich. It can't go directly on floor studs because the weight isn't well distributed. But put a layer of plywood down, then XPS, then a plywood subfloor and it won't crush. If the XPS is crushing you're probably driving a steam-roller indoors, which has it's own set of problems.

If you happen to be extra paranoid about the foam crushing then denser XPS sheets can be purchased. Money better spent than framing, in my opinion. The most common densities are 15 and 30psi, but it goes up to 100psi (Foamular goes that high, anyhow)

Framing is actually counter productive to the task of insulating. You create a thermal bridge which can transfer heat. It's also more work and money, but with no pay-back. Around here professional framers do not frame the floor before laying XPS. It's a common upgrade to put XPS on a concrete basement floor then plywood then the flooring of choice.

30psi XPS. That means the XPS can definitely take 30 pounds in one square inch before it starts to crush. Now take a 4'x8' piece of 3/4" thick plywood. If the plywood had zero flex (which it doesn't..) a piece of XPS under that piece of plywood can hold 138240 lbs.

The math:

48"x96" = 4608 sq in.

4608 sq in * 30psi = 138240 lbs.

Of course, the plywood has some flex so it's not quite that high, but it's still pretty freakin' high.

Just my opinion. People have done it many different ways without having their bus spontaneously combust.

|

|

|

11-04-2016, 05:42 PM

11-04-2016, 05:42 PM

|

#25

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

Quote:

Originally Posted by jazty

You gotta believe me on this: with a proper subfloor of 5/8" or 3/4" plywood or OSB you will not squash XPS foam. Try as you might, it will not compress. In fact, it's common practice these days to lay XPS rigid foam (of the proper density) down before pouring concrete for basements, parking garages, industrial complexes you name it. All you need to keep XPS from crushing is the proper sandwich. It can't go directly on floor studs because the weight isn't well distributed. But put a layer of plywood down, then XPS, then a plywood subfloor and it won't crush. If the XPS is crushing you're probably driving a steam-roller indoors, which has it's own set of problems.

If you happen to be extra paranoid about the foam crushing then denser XPS sheets can be purchased. Money better spent than framing, in my opinion. The most common densities are 15 and 30psi, but it goes up to 100psi (Foamular goes that high, anyhow)

Framing is actually counter productive to the task of insulating. You create a thermal bridge which can transfer heat. It's also more work and money, but with no pay-back. Around here professional framers do not frame the floor before laying XPS. It's a common upgrade to put XPS on a concrete basement floor then plywood then the flooring of choice.

30psi XPS. That means the XPS can definitely take 30 pounds in one square inch before it starts to crush. Now take a 4'x8' piece of 3/4" thick plywood. If the plywood had zero flex (which it doesn't..) a piece of XPS under that piece of plywood can hold 138240 lbs.

The math:

48"x96" = 4608 sq in.

4608 sq in * 30psi = 138240 lbs.

Of course, the plywood has some flex so it's not quite that high, but it's still pretty freakin' high.

Just my opinion. People have done it many different ways without having their bus spontaneously combust.

|

Where are you from? That math might've changed my opinion as my heaviest items wouldn't even cause an issue. Though, honestly, I haven't seen this done in ANY residential project I've worked on. Ever. Why are the pros in NY not using this method if it's as sound as that math looks? Structural stability perhaps?

Thermal bridging is not a big issue if you aren't nailing the frame into the floor. In fact the foam is rated WHEN FRAMED IN 2x4's. The theoretical R10 rating will differ based on your framing material.

I'll be back with a more informed opinion when I find out why this isn't a widespread thing in residential flooring here.

__________________

Roads? Where we're going, we don't need ... roads.

|

|

|

11-04-2016, 05:43 PM

11-04-2016, 05:43 PM

|

#26

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

I'll add, though, that for a car driving in and out over the same track repeatedly I'd frame where the wheels roll with a laid down 2x10 or the like. A car tire moving back and forth in the same spot would probably flex the whole bus floor and a 2x10 would stiffen it up a bit. I wouldn't frame for normal living spaces, though.

|

|

|

11-04-2016, 05:46 PM

11-04-2016, 05:46 PM

|

#27

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by warewolff

Where are you from? That math might've changed my opinion. My heaviest items wouldn't even cause an issue. I haven't seen this done in ANY project I've worked on. Ever. Why are the pros in NY not using this method if it's as sound as that math looks? Structural stability maybe?

|

No idea why NY wouldn't be doing it.. I'm in Ontario, Canada and it's done everywhere. We're practically neighbours.

Up here XPS is like Frank's Red Hot: we put that **** under everything!

|

|

|

11-04-2016, 06:02 PM

11-04-2016, 06:02 PM

|

#28

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

When you're right you're right. Touché.

__________________

Roads? Where we're going, we don't need ... roads.

|

|

|

11-04-2016, 06:24 PM

11-04-2016, 06:24 PM

|

#29

|

|

Bus Nut

Join Date: Mar 2015

Location: hills of sw virginia

Posts: 889

Year: 1996

Chassis: thomas

Engine: 8.3 cummins

Rated Cap: 11 window

|

Quote:

Originally Posted by jazty

You gotta believe me on this: with a proper subfloor of 5/8" or 3/4" plywood or OSB you will not squash XPS foam. Try as you might, it will not compress. In fact, it's common practice these days to lay XPS rigid foam (of the proper density) down before pouring concrete for basements, parking garages, industrial complexes you name it. All you need to keep XPS from crushing is the proper sandwich. It can't go directly on floor studs because the weight isn't well distributed. But put a layer of plywood down, then XPS, then a plywood subfloor and it won't crush. If the XPS is crushing you're probably driving a steam-roller indoors, which has it's own set of problems.

If you happen to be extra paranoid about the foam crushing then denser XPS sheets can be purchased. Money better spent than framing, in my opinion. The most common densities are 15 and 30psi, but it goes up to 100psi (Foamular goes that high, anyhow)

Framing is actually counter productive to the task of insulating. You create a thermal bridge which can transfer heat. It's also more work and money, but with no pay-back. Around here professional framers do not frame the floor before laying XPS. It's a common upgrade to put XPS on a concrete basement floor then plywood then the flooring of choice.

30psi XPS. That means the XPS can definitely take 30 pounds in one square inch before it starts to crush. Now take a 4'x8' piece of 3/4" thick plywood. If the plywood had zero flex (which it doesn't..) a piece of XPS under that piece of plywood can hold 138240 lbs.

The math:

48"x96" = 4608 sq in.

4608 sq in * 30psi = 138240 lbs.

Of course, the plywood has some flex so it's not quite that high, but it's still pretty freakin' high.

Just my opinion. People have done it many different ways without having their bus spontaneously combust.

|

right on! i put 1" foam down then 3/4 t&g advantec down, solid as sears! everything else including wheel wells was spray foamed.

|

|

|

11-04-2016, 06:32 PM

11-04-2016, 06:32 PM

|

#30

|

|

Bus Nut

Join Date: Oct 2016

Location: Pensacola and Crystal River, FL

Posts: 647

Year: 1998

Coachwork: AmTran International

Chassis: 3800

Engine: Navistar 7.6L

|

Lets face it, the housing industry is the slowest group to embrace new construction methods.

And residential contractors would still be building totally uninsulated housing if the local codes did not force them to do it.

|

|

|

11-04-2016, 07:33 PM

11-04-2016, 07:33 PM

|

#31

|

|

Bus Nut

Join Date: Sep 2016

Location: Darrington, Wa.

Posts: 304

Year: 1994

Coachwork: Genesis/Am-Tran Tall Roof

Chassis: International, 643 transmission

Engine: DT 466ci 250hp, International

Rated Cap: 86 screaming Monsters

|

So in your living area were still talking about laying 2x4 on the floor side ways. Then framing it in the shape of the walls and cabinets (loads) then cutting foam to fit the holes and sheet it.

In my shop I not thinking of any flooring or insulation but again i have no plans to go into any cold area i cant keep warm. With no sun on the bottom of the bus i think the air conditioning should work its sized for a room twice as big. were only talking about 192 square feet in the shop area.

This is a good thread for non construction guys.

|

|

|

11-04-2016, 08:17 PM

11-04-2016, 08:17 PM

|

#32

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by Geo Jeff

So in your living area were still talking about laying 2x4 on the floor side ways. Then framing it in the shape of the walls and cabinets (loads) then cutting foam to fit the holes and sheet it.

|

I wouldn't (and didn't) do all that extra floor framing. You don't need it. Take a look at the basic numbers I crunched a couple of posts back.

Metal bus floor all cleaned, painted and prepped; 2" of ship-lapped XPS foam; 5/8" tongue and groove plywood; everything else on top of that (cabinets, wood stove, propane oven, bed, couch, pilots chairs). That's how I did mine and it's working great.

My biggest regret is putting so many gall blasted screws through the plywood and into the steel floor! It was unnecessary. I used lots of construction adhesive anyway and it would have been just fine, especially once all the cabinetry is bolting the floor to the walls.

|

|

|

11-04-2016, 08:35 PM

11-04-2016, 08:35 PM

|

#33

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

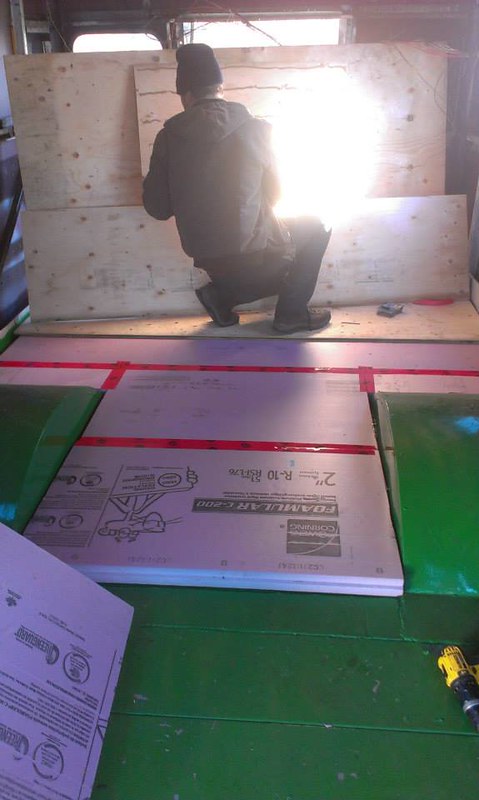

If it helps to visualize, here's a picture of me putting the floor foam in.

I staggered the foam joints with the plywood joints and put loads of PL Premium adhesive between the metal floor, foam and plywood. It holds like a champ. I had to pull out a square of the floor when I was building the shower pan and the foam pulled the paint from the steel before breaking in most places.

JakeC did an even better job than I did. He skipped the screws. I would have PL Premiumed the schnitzel out of it, though. http://www.skoolie.net/forums/f11/project-brutus-5059.html

|

|

|

11-05-2016, 07:38 AM

11-05-2016, 07:38 AM

|

#34

|

|

Bus Nut

Join Date: Jul 2016

Posts: 543

|

Here is my take on floors. I use to design and build risers for dance performance. A 3/4 sheet of plywood under "normal" use can handle the stress of people walking on it but if you have a 100# lady with spike heals her heal puts over 400# per square inch pressure on the plywood. we would double up the plywood on 12" centers of 2x4 or 2x6. Now think of an appliance at 200# + with small feet under it. I would like to see extra support for the appliances then just plywood on top of foam insulation.

JMO hope it helps Gordon

|

|

|

11-05-2016, 09:28 AM

11-05-2016, 09:28 AM

|

#35

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by Tootalltechie

have a 100# lady with spike heels her heal puts over 400# per square inch pressure on the plywood.

|

Well, if it's a 100lb lady standing with all her weight on the one heel, then it's only 100lb per sq in. If she's jumping up and down then it very well could be 400lbs of dynamic loading.

But then what happens is the plywood distributes that weight. If you had a small lady jumping on top of you with her heals it would hurt.. A lot.. Maybe even impale you.

If you had that same lady jumping on top of a piece of plywood that was placed on top of you it would be much more comfortable.. but still probably not enjoyable.

From experience: you will never have a load inside your normal living space that will crush the XPS foam under a sheet of 3/4" plywood. You just won't.. I dance on my floor all the time and I'm 190lbs. I'll grab a pair of high heels for my next dance session and get back to you...

|

|

|

11-05-2016, 09:30 AM

11-05-2016, 09:30 AM

|

#36

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Also, don't forget that in a bus the foam and plywood are not over top of wooden stud framework. They are laying on top of a flat metal framework. All the stresses are spread out.

Put a piece of plywood over a 24" OC stud framework and you'll probably feel some flex if you jump between the studs. Put that same plywood on top of flat concrete and... No flex, no crushing, no give.

|

|

|

11-07-2016, 06:37 PM

11-07-2016, 06:37 PM

|

#37

|

|

Bus Nut

Join Date: Oct 2016

Location: Iowa

Posts: 447

Year: 1989

Chassis: International

Engine: 9.L

Rated Cap: 64

|

Quote:

Originally Posted by Jolly Roger

I plan on going the insulation underside route.

A floating floor is exactly that.

If you read the directions it says to cut it 1/8? Short to allow room for expansion and contraction and the trim boards to be installed in the same manner for the same reasons.

I did the whole floating floor in my house before I did my bus.

There are areas in my house that I cut to tight and when we go from AC to windows open the floor likes to bow/buckle in places.

I would think that in a moving platform that you would want to leave even more wiggle room to accommodate the floating in the floor.

To be a thick quarter round or make your own trim is needed.

I built every wall, or whatever to securely fasten directly to the steel floor so all of my spaces are floored separately to wiggle as needed and that's why I decided to insulate underside instead of inside. I used 1/4" foam for most and and little bit of some carpet underlay that was fibre material with plastic for around the transmission motor area? Trying to deaden the sound a little.

Hope this helps.

Sorry another option I just started daydreaming about was clean/prep and spray foaming the underside?

It would be easier and maybe cheaper before you put a lot of mess in the way.

I do commercial construction and see them spray galvanized metal and they can do a 3" spray on the backer board the steel I-beam then to the wall and then a 8" stud and never touch wher they don't need to. .

Hope this helps

|

That spray foaming the underside is a damn good idea, of course spray after you have everything installed first. Would be a great sound deadener.

|

|

|

11-08-2016, 07:20 AM

11-08-2016, 07:20 AM

|

#38

|

|

Bus Geek

Join Date: Oct 2016

Location: Essex, MD

Posts: 3,738

Year: 1999

Coachwork: Blue Bird

Chassis: Blue Bird TC RE 3904, Flat Nose, 40', 277" wh base

Engine: 8.3L Cummins ISC 260hp, MT643, 4.44 rear

Rated Cap: 84 pax or 1 RV; 33,000lbs

|

Quote:

Originally Posted by Stu & Filo. T

It's also been mentioned that speed kills,

I contend it's the uncontrolled stop that does it.

|

It doesn't matter if it is controlled or not. It's the sudden stop (g force) that kills. Works for speed in both directions.

|

|

|

11-08-2016, 07:56 AM

11-08-2016, 07:56 AM

|

#39

|

|

Bus Geek

Join Date: Oct 2016

Location: Essex, MD

Posts: 3,738

Year: 1999

Coachwork: Blue Bird

Chassis: Blue Bird TC RE 3904, Flat Nose, 40', 277" wh base

Engine: 8.3L Cummins ISC 260hp, MT643, 4.44 rear

Rated Cap: 84 pax or 1 RV; 33,000lbs

|

Quote:

Originally Posted by jazty

Well, if it's a 100lb lady standing with all her weight on the one heel, then it's only 100lb per sq in. If she's jumping up and down then it very well could be 400lbs of dynamic loading.

I'll grab a pair of high heels for my next dance session and get back to you...

|

1) Her heel isn't 1 square inch; it's smaller. Maybe not even a 1/4"^2 in some cases. If she is to jump with that thin a heel, something is going to give. Either the plywood, the shoe, or her ankle.

2) Didn't happen if there's no video. We're waiting...

|

|

|

11-24-2016, 10:53 PM

11-24-2016, 10:53 PM

|

#40

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

Quote:

Originally Posted by Brewerbob

1) Her heel isn't 1 square inch; it's smaller. Maybe not even a 1/4"^2 in some cases. If she is to jump with that thin a heel, something is going to give. Either the plywood, the shoe, or her ankle.

2) Didn't happen if there's no video. We're waiting...  |

This was what I was getting at. I get that people can install a floating floor to an acceptable subjective standard without properly framing -- doesn't mean it's right. The stuff I used was Foamular 150, 7.5R, 15psi. Under light load it'd be fine. But for long term use and, especially if I am thinking about putting heavy appliances in a rocking bus that will then torque and distribute uneven weight to each of the legs as I drive along, it's just not the right way to do it. I still won't concede that frameless is the correct application for this particular product.

That being said, I didn't frame. And that being said, the floor doesn't feel as solid as it would have had I framed. I don't know if I made the right decision, but it is a trade off. I did it to make the floor as air tight as possible and to ward off thermal bridging. Just sayin'.

__________________

Roads? Where we're going, we don't need ... roads.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|