|

|

04-21-2015, 12:27 AM

04-21-2015, 12:27 AM

|

#161

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quick update

Last few days I was working on my kitchen slide out box. It is 2'x13'x6'.

As the previous box this box frame I build using 2"x2" aluminum angles riveted together with 1/4" solid aluminum rivets. I use my own build hydraulic compression tool and it works great.

When I need to make a bunch of the same pieces I usually make a template. This extra step pays for itself by saving time and making all pieces exactly the same. I needed a bunch of angles with a bunch of holes drilled, so I made a steel template for drilling:

Here is an air drier I build another day. I need it for plasma cutter to have dry air. I used an old laying around refrigerant receiver. I cut a hole on top and welded a piece of 2" steel pipe. The inlet pipe goes to the bottom inside. I used a silica gel crystals which is used as kitty litter. This silica gel crystals are a great absorbent and help to dry air. The whole 4 pound bag was $ 6 making it wery affordable.

__________________

Here is my conversion thread:

https://www.skoolie.net/forums/f11/98-bluebird-tc2000-conversion-2-feet-roof-raise-3-slideouts-9728.html

|

|

|

04-21-2015, 08:47 AM

04-21-2015, 08:47 AM

|

#162

|

|

Bus Geek

Join Date: Aug 2011

Location: Stony Plain Alberta Canada

Posts: 2,937

Year: 1992

Coachwork: Bluebird

Chassis: TC2000 FE

Engine: 190hp 5.9 Cummins

Rated Cap: 72

|

Dude I love this thread.

You and I share so many of the same ideas.

Don't forget to make sure the air cools before entering the dryer. This is important to condense the moisture. Most will be able to be drained off before it reaches the dryer.

I have to make the same set up soon so I can use my new plasma.

Nat

__________________

"Don't argue with stupid people. They will just drag you down to their level, and beat you up with experience."

Patently waiting for the apocalypses to level the playing field in this physiological game of life commonly known as Civilization

|

|

|

04-21-2015, 12:30 PM

04-21-2015, 12:30 PM

|

#163

|

|

Bus Crazy

Join Date: Feb 2012

Location: Salt Lake City Utah

Posts: 1,635

Year: 2000

Chassis: Blue Bird

Engine: ISC 8.3

|

That's a nice looking drier. I confess: I entirely forgot about feeding my plasma cutter dry air. I've been using an electric compressor with 60 gallon tank oriented vertically; the inlet from the pump and the outlet to the air line are both on the top. I drain the tank.. sometimes.. ;) Oh, I have a little water separator on the outlet as well, and it occasionally gets drained too.

Last time I took steel for recycling I had a receiver/dryer they wouldn't accept; they said it had to be cut open first. So back at home I cut off the end with the hoses and still have the cylinder kicking around the shop. Now I know what I should do with it!

How full do you fill the kitty litter? Does the air need to actually travel through the drying media, or would that just cause it to pick up dust?

|

|

|

04-21-2015, 02:20 PM

04-21-2015, 02:20 PM

|

#164

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quote:

Originally Posted by family wagon

That's a nice looking drier. I confess: I entirely forgot about feeding my plasma cutter dry air. I've been using an electric compressor with 60 gallon tank oriented vertically; the inlet from the pump and the outlet to the air line are both on the top. I drain the tank.. sometimes.. ;) Oh, I have a little water separator on the outlet as well, and it occasionally gets drained too.

Last time I took steel for recycling I had a receiver/dryer they wouldn't accept; they said it had to be cut open first. So back at home I cut off the end with the hoses and still have the cylinder kicking around the shop. Now I know what I should do with it!

How full do you fill the kitty litter? Does the air need to actually travel through the drying media, or would that just cause it to pick up dust?

|

Firs of all your plasma cutter needs dry air. It doesn't matter how big your tank is. I have huge over 100 gal receiver and I drain it (sometimes ;) )

Now some details:

1. I put plastic wire sponge (used for cleaning pots and pans) on the bottom where air enters the dryer. This keep silica inside when you disconnect your hose.

2. I filled it right up with silica.

3. I put the same plastic sponge in the top 2" pipe near air exit for the same reason to keep silica inside.

All air goes through the media, which is the desiccant.

The dust.... you do get some dust at the beginning and I just let it blow out for a bit. I keep standard filter/water separator (useless thing for removing water) on my plasma cutter and it will catch the dust.

BTW silica can be reused many times. All I need is to open the dryer (this is why I used 2" pipe and cap) pull sponge out, shake silica out, put into old cast fry pan and put it into oven for some time to dry.

__________________

Here is my conversion thread:

https://www.skoolie.net/forums/f11/98-bluebird-tc2000-conversion-2-feet-roof-raise-3-slideouts-9728.html

|

|

|

05-28-2015, 04:53 PM

05-28-2015, 04:53 PM

|

#165

|

|

Skoolie

Join Date: Aug 2014

Posts: 160

Coachwork: -

Chassis: -

Engine: -

|

Hey Vlad,

how is it goin'?

Any updates on your dream machine?

Cheers,

thjakits

|

|

|

05-28-2015, 05:45 PM

05-28-2015, 05:45 PM

|

#166

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quote:

Originally Posted by thjakits

Hey Vlad,

how is it goin'?

Any updates on your dream machine?

Cheers,

thjakits

|

I currently work on kitchen slide out. It is basically as same as living room just a bit smaller. It is 22" deep vs 48" living room. It has the same slide out system, the same frame.

I don't know if it is worth to gust "fill up" my conversion. Some threads are getting so long it is impossible to read them through.

|

|

|

05-28-2015, 05:51 PM

05-28-2015, 05:51 PM

|

#167

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Fighting rust.... any ideas?????

I need to remove a bunch of rust from bus frame.

I tried some "magic fluids" and they work only in their inventors imagination....

Does somebody have REAL experience and REAL success to remove heavy rust from vehicle frame?

I do understand I will have to remove flaking rust and I have needle scaler for this.

There is no way i can submerge the whole frame in acid and use galvanic effect to remove rust.

Please share some info. This is my REAL PITA......

|

|

|

05-28-2015, 06:29 PM

05-28-2015, 06:29 PM

|

#168

|

|

Skoolie

Join Date: Aug 2014

Posts: 160

Coachwork: -

Chassis: -

Engine: -

|

...great!

22 + 48 = fairly tight squeeze if they are both in. Did you plan to have the bus "functional" with all slides in? ....or just assume, that the slides will go out anyway anywhere?

Cheers,

thjakits

PS: Sorry, can't really help you with the chassis rust. THe only thing I ever ran across that probably was a similar heavy rust is a fishing vessel. The guys there used some seriously bad sh** (needed to wear masks). Applied with a brush after "picking the rust" (basically spend quality time with a heavy welding hammer chipping rust).

After that stuff went on, everything went BLACK. Finished off with some specific ship paint - good for 1/2-3/4 year and the whole fun started over....

Surface was still rough, but at least protected for a while....

Unless there is some new Super rust-remover-changer out there, I think your best option is to go section by section - though it will be serious work......

|

|

|

05-28-2015, 09:04 PM

05-28-2015, 09:04 PM

|

#169

|

|

Skoolie

Join Date: Mar 2010

Location: Texas

Posts: 218

Year: 1997

Coachwork: AmTran

Chassis: Genesis

Engine: DT466

Rated Cap: 84

|

Ospho works well. Turns the rust black, prepares the surface for priming.

|

|

|

05-29-2015, 04:24 AM

05-29-2015, 04:24 AM

|

#170

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quote:

Originally Posted by thjakits

...great!

22 + 48 = fairly tight squeeze if they are both in. Did you plan to have the bus "functional" with all slides in? ....or just assume, that the slides will go out anyway anywhere?

Cheers,

thjakits

|

You only drive hours but stay days.... This is why I decided to have such a large (deep) living room area.

Also as I said before I want everyone sit in their seat with proper seat belt while we drive. I don't want chase people while I drive. You never know what can happen next second on the road. Everyone will look into window, or play their tablet, or watch tv, or whatever... If somebody is tired, we will stop in safe place and take a rest.

BTW It will take a few seconds to deploy at least kitchen side and have much more room to move around. I will use hydraulic cylinders and electric solenoids to control slide outs.

__________________

Here is my conversion thread:

https://www.skoolie.net/forums/f11/98-bluebird-tc2000-conversion-2-feet-roof-raise-3-slideouts-9728.html

|

|

|

05-29-2015, 04:30 AM

05-29-2015, 04:30 AM

|

#171

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quote:

Originally Posted by Timelord

Ospho works well. Turns the rust black, prepares the surface for priming.

|

Thanks for reply....

Anyone else? Any real stories????

__________________

Here is my conversion thread:

https://www.skoolie.net/forums/f11/98-bluebird-tc2000-conversion-2-feet-roof-raise-3-slideouts-9728.html

|

|

|

05-29-2015, 08:36 AM

05-29-2015, 08:36 AM

|

#172

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

I have tested and used a product called "Restore" by Quest Chemical for many years on the rebar armatures in my cement sculptures. Great stuff. It is a tannic acid based compound that converts the surface oxides into a stable, organic compound. Different chemistry & process than Ospho and other products. It also contains a very tough polymer than rises to the surface for added protection. To my knowledge, it is the only such product that is rated as a final finish.. All the others I have seen are rated as a primer only and require a coat of paint to get the full benefits.

|

|

|

06-01-2015, 12:14 AM

06-01-2015, 12:14 AM

|

#173

|

|

Bus Nut

Join Date: Apr 2010

Location: Lebanon, IN

Posts: 272

Year: 1998

Chassis: TC 2000 bluebird

Engine: 5.9 cummins

Rated Cap: 66

|

Rust

I just spent the past three weekends dealing with all the rust from the rear axle back on my 1998 bluebird tc2000FE.

I used two different needle de-scalers on any heavy rust and then flap discs to smooth the surface and remove any loose paint left over. Then an air die grinder with a knotted wire brush to get in cracks and crannies. I coated every surface when ready with rustoleum rust converter. Then a coat of rustoleum gloss black paint. Most of the rust was on the frame. And the rear air tank used for the rear suspension. I replaced all the body hold down clips as they were heavily rusted. I have seen too many photos of bus accidents where the body was thrown off the frame. I had to deal with this before mounting the rear water tank. The rear of the bus had the most rust. The body was heavily undercoated and has fared very well.

|

|

|

06-01-2015, 04:35 PM

06-01-2015, 04:35 PM

|

#174

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Quote:

Originally Posted by miltruckman

I just spent the past three weekends dealing with all the rust from the rear axle back on my 1998 bluebird tc2000FE.

I used two different needle de-scalers on any heavy rust and then flap discs to smooth the surface and remove any loose paint left over. Then an air die grinder with a knotted wire brush to get in cracks and crannies. I coated every surface when ready with rustoleum rust converter. Then a coat of rustoleum gloss black paint. Most of the rust was on the frame. And the rear air tank used for the rear suspension. I replaced all the body hold down clips as they were heavily rusted. I have seen too many photos of bus accidents where the body was thrown off the frame. I had to deal with this before mounting the rear water tank. The rear of the bus had the most rust. The body was heavily undercoated and has fared very well.

|

So I will be in your shoes soon......

As I understand if you have just a bit of rust(which is an iron hydroxide) you can simply convert it into black iron oxide and paint it over.

In my case just like in your I have heavy rust and it musy be removed completely or to convertable thin layer.

To remove heavy rust you can mechanically remove it or use some chemicals to remove it.

Did you try any chemicals to help to remove rust?

On flat surface it is easy to remove rust mechanically but considering frame shape it is a real PITA....

|

|

|

06-02-2015, 12:16 PM

06-02-2015, 12:16 PM

|

#175

|

|

Bus Nut

Join Date: Apr 2010

Location: Lebanon, IN

Posts: 272

Year: 1998

Chassis: TC 2000 bluebird

Engine: 5.9 cummins

Rated Cap: 66

|

Vlad,

I have been working on machinery for many years and have found rust removal chemicals to be a waste of time. I usually remove the heavy rust with a Descaler then grind or wire brush the rest off with an angle grinder. The knotted/twisted brushes and flap discs work the best. To get in the tight areas an air die grinder with a twisted coarse brush works well. Sand blasting is a bad idea as it drives sand into all the moving parts causing accelerated wear and contaminating anything it gets into that is lubricated or has moving parts. You typically have to pull more apart than you had planned or wanted to, to get at all the rust. For example, I pulled the rear air tank and disassembled the air suspension valve bracket and linkage to get at all the rust behind the axle. And those body mount clips run only about $8(us) ea. so they were replaced.

In the front I pulled the radiator and replaced it, and while I had it out, I replaced the alternator, water pump, front main seal, idler pulley, belts, and rebuilt both AC compressors on the engine. Then I installed a 10" wide piece of channel iron behind that flimsy front bumper and mounted a front receiver hitch.

In the rear I am mounting a 110gl stainless steel water tank and a receiver hitch after reinforcing the rear bumper and replacing the mounting brackets. I can send you some photos of the work in the rear if you would like. An email would be easier as posting photos from my phone is tricky.

Bill

|

|

|

06-02-2015, 08:36 PM

06-02-2015, 08:36 PM

|

#176

|

|

Skoolie

Join Date: Aug 2014

Posts: 160

Coachwork: -

Chassis: -

Engine: -

|

By mistake posted on the wrong thread (....I was messing up Sojourner's build with this...)

Re-post:

Would Sand Blasting (...or other media) be an option??

Probably not even costlier than days and weeks with the de-scaler (after all this will cost a fare amount of time and electricity).

Besides "Restore" -you might want to look into the Corrosion-X products.

There is a HD version, that should stick extremely well to the frame.

Corrosion-X is all the rage in aviation!! It creeps into any nook and cranny and sticks fairly well....

Then there is SP-400 Industrial Protection by CRC - I only know the spray cans, but I love the stuff. Goes on fairly well, you can re-coat a few times (let it dry between coats), stays extremely flexible (like a wax) and it is semi-transparent, so you can watch what is going on underneath.

[Note: DON'T use the lighter 350 or 200 versions!! SP-400 is the Heavy Duty thing!]

Corrosion-x also has De-rust products, but I don't know how well these work for heavy rust....

Obviously the main-chore is to get the rust off....

After that you might even just opt for a heavy gear oil - heat it up and spray it on and let dust do the rest!

Cheers,

thjakits

|

|

|

06-02-2015, 08:44 PM

06-02-2015, 08:44 PM

|

#177

|

|

Skoolie

Join Date: Aug 2014

Posts: 160

Coachwork: -

Chassis: -

Engine: -

|

Quote:

Originally Posted by Vlad

You only drive hours but stay days.... This is why I decided to have such a large (deep) living room area.

Also as I said before I want everyone sit in their seat with proper seat belt while we drive. I don't want chase people while I drive. You never know what can happen next second on the road. Everyone will look into window, or play their tablet, or watch tv, or whatever... If somebody is tired, we will stop in safe place and take a rest.

BTW It will take a few seconds to deploy at least kitchen side and have much more room to move around. I will use hydraulic cylinders and electric solenoids to control slide outs.

|

Hey Vlad,

I fully agree with your statement above - that's what it is all about, really.

However, you didn't answer my question: Is the bus "functional" with the slides in??

I fully understand, that this is NOT the preferred way to operate The Bus, and you certainly would want to pop out the slides whenever you stop.

My question is geared more like to "undesirable" situations, which you just couldn't avoid:

Traffic Jams (landslide, flood, any number of occasions) - situations you certainly would avoid IF YOU KNEW!

Any situation, where you CANNOT or do not want to pull the slides out.

...is your bus still functional? Can you squeeze through to the bathroom and bed-room? Is the kitchen workable, dito the living room?

OR is there NO WAY to use the bus without sliding out?

Cheers,

thjakits

|

|

|

06-03-2015, 05:13 PM

06-03-2015, 05:13 PM

|

#178

|

|

Skoolie

Join Date: Oct 2014

Location: Maple Ridge BC Canada

Posts: 200

Year: 1998

Coachwork: Blue Bird

Chassis: TC2000 Rear engine

Engine: Cummins 8.3; MD3060

Rated Cap: 84

|

Rust fighting

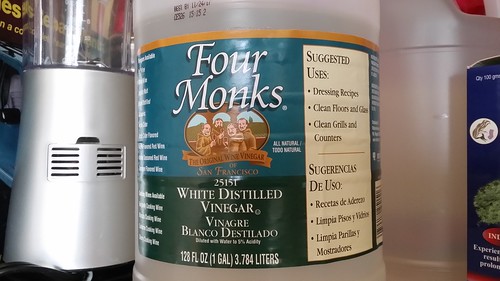

Here is my rust fighting project.

Here is a picture of surface that was treated with Evapo-Rust. I put a piece of rag and wet it a few times during 2 or 3 days:

Not much of a difference......

After some research I decided to try the most available chemicals. I wet a piece of rag only once and left it overnight. Here are results:

Not bad at all.

Now what did I use????

Here we go:

It looks very promising, doesn't it?

Another chemicals I will try is Oxalic Acid. It is dirt cheap just like vinegar.

Now I will need to find the way to make them thicken them up, make a gel. Any ideas???

__________________

Here is my conversion thread:

https://www.skoolie.net/forums/f11/98-bluebird-tc2000-conversion-2-feet-roof-raise-3-slideouts-9728.html

|

|

|

06-03-2015, 07:34 PM

06-03-2015, 07:34 PM

|

#179

|

|

Bus Geek

Join Date: Aug 2011

Location: Stony Plain Alberta Canada

Posts: 2,937

Year: 1992

Coachwork: Bluebird

Chassis: TC2000 FE

Engine: 190hp 5.9 Cummins

Rated Cap: 72

|

Cornstarch?

Nat

__________________

"Don't argue with stupid people. They will just drag you down to their level, and beat you up with experience."

Patently waiting for the apocalypses to level the playing field in this physiological game of life commonly known as Civilization

|

|

|

06-03-2015, 08:07 PM

06-03-2015, 08:07 PM

|

#180

|

|

Bus Crazy

Join Date: Feb 2012

Location: Salt Lake City Utah

Posts: 1,635

Year: 2000

Chassis: Blue Bird

Engine: ISC 8.3

|

Pectin is used for thickening fruit jams, jellies, etc.. There's a little bit of a science to it; I guess if the pH is too low then it won't set well. I'm not sure whether it would work with vinegar. Pacific Pectin

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|