Quote:

|

special pump set up just for flushing and filling the systems to get all of the air out

|

I used a cheap sprayer pump from Tractor Supply, one end in a bucket the other into a T I put into the main loop, works good for getting the coolant in. I also wired the pump in the boiler with a toggle switch so I could use it to help circulate.

Quote:

|

how many loops are you talking about? Do you actually heat by zones with the ability to shut off certain areas?

|

I have four loops, three controlled by thermostat the fourth by switches on the dash. I don't actually shut off an area, just turn on the pump that supplies hot water to that loop.

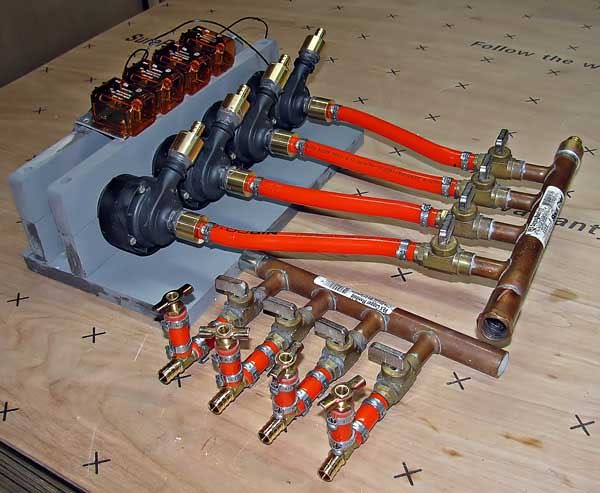

This is the manifold and pumps for the heating system. The copper pipe on the right of the supply manifold is in the main loop, the thermostats turn the pump on or off. The lower manifold is the return at the end of each loop, again the large copper pipe is in the main loop.

Each of the water/air heaters has a fan. There is a sensor on each fan so that it won't come on if the water in the loop isn't warm enough so they won't blow cold air. There is also a manual switch for each fan. It works really well, when temperature of thermostat is attained the loop pump will turn off, when the water in that loop cools the fan will also shut off.

In practice from a cold start, I start the boiler and turn up the thermostats and turn on all of the blowers. From 0 it takes about an hour to get up to 68 degrees or so. When it's nice and cumfy I turn off the blowers and floor maintains heat pretty well. If a room seems cold I simply turn on the blower in that room.