|

|

01-30-2017, 07:52 PM

01-30-2017, 07:52 PM

|

#21

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

|

|

|

01-31-2017, 12:08 AM

01-31-2017, 12:08 AM

|

#22

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

Quote:

Originally Posted by Goatherder

|

Well, that didn't work worth a sh!t, now did it?

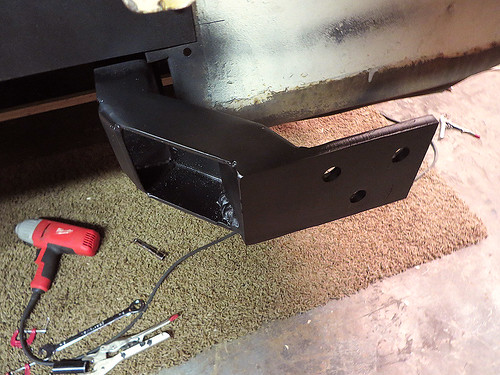

So today I finished welding up the trailer hitch, which ties in structurally with the frame reinforcements and will also help support the rear bumper...which in turn will support the rear deck. Intended to fab my own hitch receiver but my 2.5" square tube had a raised seam on the inside which precluded me from sliding any 2" tube into it. So I went to my local steel/industrial supply, bought a 24" hitch receiver for $50 and then raided their shorts rack & dumpster for another $20. Came home w/ a couple hundred pounds of steel stock...

Anyway, here's the hitch assembly all welded up into what looks like some kinda Jesus cross. And a pic of it welded into the bus. It protrudes beyond the bumper about a foot.

I'll fab a plate w stiffeners and safety chain eyes that bolts to the outside of the bumper and clamps the receiver in position. But it's pretty damn solid now. I stuck a 6ft 2" sq tube in the receiver and jumped up and down like a monkey. No flexing or creaking or relative motion that I could see.

And...we'll see if the video posts.

http://vid36.photobucket.com/albums/...ps6sr0tfgi.mp4

|

|

|

01-31-2017, 12:49 PM

01-31-2017, 12:49 PM

|

#23

|

|

Bus Nut

Join Date: Feb 2014

Location: Cuyahoga Falls Ohio

Posts: 592

Year: 1997

Coachwork: Startrans

Chassis: Ford e-350 single wheel

Engine: 5.4 litre

Rated Cap: 12

|

I see you installed some good tow hooks. I have used mine several times. I like your build.

|

|

|

01-31-2017, 05:22 PM

01-31-2017, 05:22 PM

|

#24

|

|

Bus Nut

Join Date: Oct 2014

Location: Kent, WA (Seattle)

Posts: 414

Year: 1987

Engine: 6.9L Diesel

|

Keep those pix coming! I'm loving it!

|

|

|

02-02-2017, 08:56 PM

02-02-2017, 08:56 PM

|

#25

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

|

|

|

02-03-2017, 07:56 AM

02-03-2017, 07:56 AM

|

#26

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

Very excellent! Have you considered flat expanded metal for decking? Can be had in heavy gauge and also stainless.

|

|

|

02-03-2017, 09:00 AM

02-03-2017, 09:00 AM

|

#27

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

Quote:

Originally Posted by Tango

Very excellent! Have you considered flat expanded metal for decking? Can be had in heavy gauge and also stainless.

|

A friend has that on his roof rack. But stainless would be $$$ and mild steel would probably have to be powder coated (again $$) to keep it from rusting from foot traffic. Also...you have to weld the perimeter to a frame and weld EVERY SINGLE TAB in order to keep it from bending under load between the supports. Thats alotta tack welds.

Other considerations are poultry/kennel grating, MDO plywood either painted with roll-on bedliner or layered with rubber matting, or some 5/4 yellow cedar I saw on CL last night...

|

|

|

02-05-2017, 09:11 PM

02-05-2017, 09:11 PM

|

#28

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

OR...maybe just some yellow cedar. It'll turn gray when it weathers.

|

|

|

02-06-2017, 09:23 AM

02-06-2017, 09:23 AM

|

#29

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

Another option I have been considering is fake wood deck material. Lighter than real wood, does not shrink or swell, won't ever rot and does not need to be stained or painted.

|

|

|

04-03-2017, 07:13 PM

04-03-2017, 07:13 PM

|

#30

|

|

Mini-Skoolie

Join Date: Jan 2017

Posts: 20

|

love this!!

|

|

|

04-11-2018, 02:12 PM

04-11-2018, 02:12 PM

|

#31

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

Quote:

Originally Posted by Tango

Welding on frames is frowned upon and even pronounced "verboten" by GM in several tech flyers. But, given that the tail section is not really subjected to the kind of loading as the central portion, I expect it can be gotten away with as long as the weight applied to the extension is minimal.

But personally, I went with with bolt ons just to be safe. And, I also had to spread the distance between the rails while I was at it in order to make room for a place to hang a spare tire. Here's a couple of pix...

C-Channel frame extensions

The actual deck frame will rest on top of these and also bolt in place. That way if some nitwit (such as myself) ever damages part of the deck it will be a lot easier to repair than if all welded.

I have all the steel cut for the deck frame and will likely start assembling it fairly soon. The only weight it will carry will be a little Honda genny and, just maybe, a small dirt bike. Still thinking that one through. |

I know this is an old thread but I'm thinking about putting a 2 or 3 foot deck on the back to accommodate my mini split unit and maybe a dirt bike safely. Tango, do you have any pics from the underside so I can get a rough idea? Can I hire you to design one for me?

|

|

|

04-11-2018, 10:04 PM

04-11-2018, 10:04 PM

|

#32

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

I will have to dig but I don't recall taking much on the underside. Pretty simple on mine. I had a sheetmetal shop bend some 3/16" or 1/4" "C" channel extensions to fit inside the existing frame, then bolted them in place. Welding on frames need to be very limited and done just right.

The spread you see on my extensions was just to accommodate a spare tire, the carrier for which, I fit between the extended frame rails. The flat plates are where the actual deck will mount. The weight, however, will be carried on top of those plates.

Just looked and don't have any pix below other than the "before" shot of the frame below but will be happy to share any info I can.

The "C" channels fit inside these rails and are held in place with 5/8" bolts.

|

|

|

04-11-2018, 10:17 PM

04-11-2018, 10:17 PM

|

#33

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

Be aware that every Ford Van cutaway chassis that is built into a finished vehicle by a coachbuilder such as Bluebird, Collins, Winnebago, etc probably has had an extension welded onto the aft end of the frame to make it the necessary length for the particular vehicle being built. Apparently this is standard practice and pretty much blows the "NEVER WELD ON THE FRAME" theory.

Mine had about 18" of extension butt welded to the Ford C-channel frame. The welding looked like ass. No way would I trust it to support my rear deck; it would most certainly crack along that nasty weld without reinforcement. The bridges I welded in are rock solid, and I've given it the test on washboard gravel at speed. My back deck is now 5x7 and weighs about 500 lbs.

The ONLY way that bolt-on reinforcements would be anywhere near as strong as welded i s if the HOLES for the bolts that attach them are precisely drilled & reamed so that the bolts have a DRIVE FIT into the bolt holes. That means you have to pound them in and they fit TIGHT into both the frame and reinforcement piece. If not, there can be movement and the only thing that is preventing that movement is the friction between the two metal surfaces.

Don't be a ninny. WELD it.

PICS:

https://drive.google.com/file/d/1JMC...ew?usp=sharing

https://drive.google.com/file/d/1YAs...ew?usp=sharing

https://drive.google.com/file/d/18Xw...ew?usp=sharing

https://drive.google.com/file/d/1b-b...ew?usp=sharing

|

|

|

04-12-2018, 09:11 AM

04-12-2018, 09:11 AM

|

#34

|

|

Bus Nut

Join Date: Feb 2018

Location: New Jersey

Posts: 335

Year: 2004

Coachwork: Corbeil

Chassis: Ford

Engine: Ford PowerStroke Diesel 6.0

Rated Cap: GVWR 11,500

|

Quote:

Originally Posted by Goatherder

|

That is some snazzy fabricating and a handsome pup! Thanks for sharing!

|

|

|

04-13-2018, 10:07 AM

04-13-2018, 10:07 AM

|

#35

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

The "C" channels I fabbed don't rely on friction. They are a snug fit inside the factory C frame. The bolts simply pull the two together and prevent in & out movement. And given that between them they add up to about a half inch of steel, that is way more than needed to support a 24" extension.

Also a good idea to check with the manufacturer before doing any welding or drilling on any frame. Chevy has very specific guidelines regarding both welding and drilling on their frames.

|

|

|

04-13-2018, 10:33 AM

04-13-2018, 10:33 AM

|

#36

|

|

Skoolie

Join Date: Aug 2016

Location: Olympia, WA

Posts: 138

Year: 2004

Coachwork: Collins

Chassis: E450 Ferd

Engine: 6.0L Diesel

Rated Cap: 20 window lickin Jeffies

|

Yep, you are correct. Those C-channels look plenty stout for what you are doing.

In my case, I knew I would be hanging 5 to 600 pounds off the stern of the bus, and pounding the snot out of it on gravel roads, so I needed structure under the bus that would accommodate that type of abuse. And given that the bitter end of the frame already had an extension welded to it, I feel no remorse about adding a little more welding in the same general area.

|

|

|

04-13-2018, 11:06 AM

04-13-2018, 11:06 AM

|

#37

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

Mine was just the opposite. Wayne cut a few feet off the rear of the ton and a half Chevy frame to fit a shorty body. And as you can tell by that one pic...they did a really sloppy torch job of it!

|

|

|

04-13-2018, 12:43 PM

04-13-2018, 12:43 PM

|

#38

|

|

Bus Nut

Join Date: Sep 2016

Location: NY

Posts: 487

Year: 2000

Coachwork: Carpenter

Chassis: International 3800

Engine: T444E

|

Quote:

Originally Posted by Tango

Mine was just the opposite. Wayne cut a few feet off the rear of the ton and a half Chevy frame to fit a shorty body. And as you can tell by that one pic...they did a really sloppy torch job of it!

|

And Tango, how did you go about fabricating those C channels? I'd like to mimic your build, no widening of the frame, just to support my mini split and moped. I have never fabricated anything and might just go to a shop but it's be nice to be able to describe what I want to them. Can you walk me through the process?

|

|

|

04-13-2018, 10:37 PM

04-13-2018, 10:37 PM

|

#39

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

The C channels were a project I handed off to my local sheet metal shop. I just took (very careful) measurements and they did the rest. I can't fold steel that thick. From there I just drilled and bolted using grade 8 flange bolts. Stout.

|

|

|

04-16-2018, 02:33 PM

04-16-2018, 02:33 PM

|

#40

|

|

Skoolie

Join Date: Nov 2011

Posts: 172

Year: 1993

Coachwork: BlueBird

Chassis: GMC

Engine: GMC

Rated Cap: 42

|

The Best

This was an example of the Skoolie board at its best. There was a hot button topic (welding vs Bolting to the frame) and there was a free flow of information with no name calling and no drama. A hearty thanks to the posters because I learned a lot and will be better informed when I put a hitch on my bus. Thanks again.

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|