|

|

03-12-2018, 05:40 PM

03-12-2018, 05:40 PM

|

#41

|

|

Skoolie

Join Date: Aug 2017

Location: Phoenix, AZ

Posts: 228

Year: 1997

Coachwork: Blue Bird

Chassis: AARE 3903

Engine: Cummins 8.3L 12v

Rated Cap: 78

|

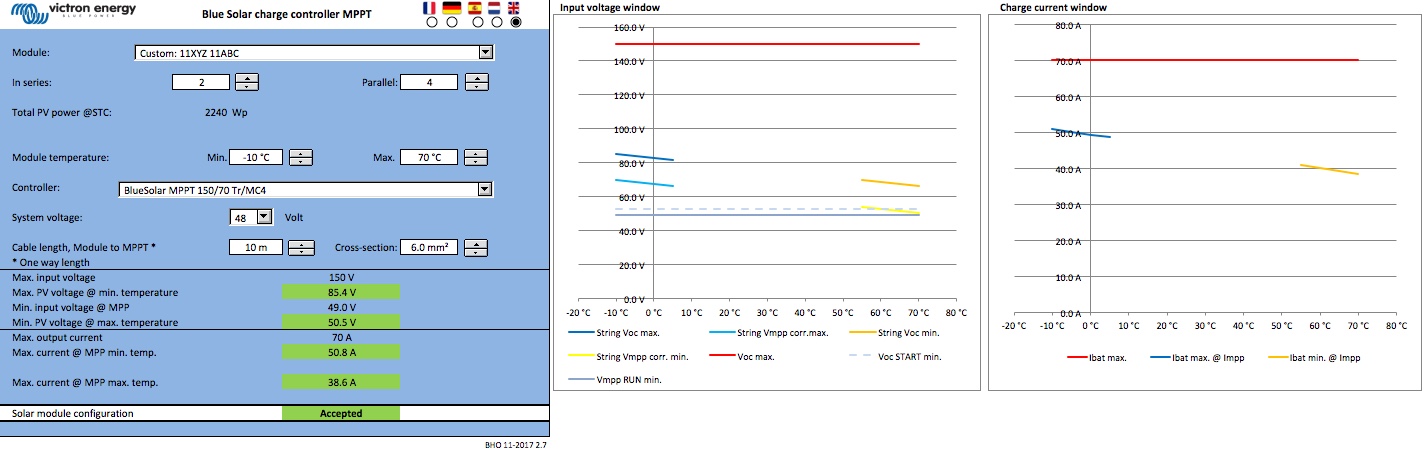

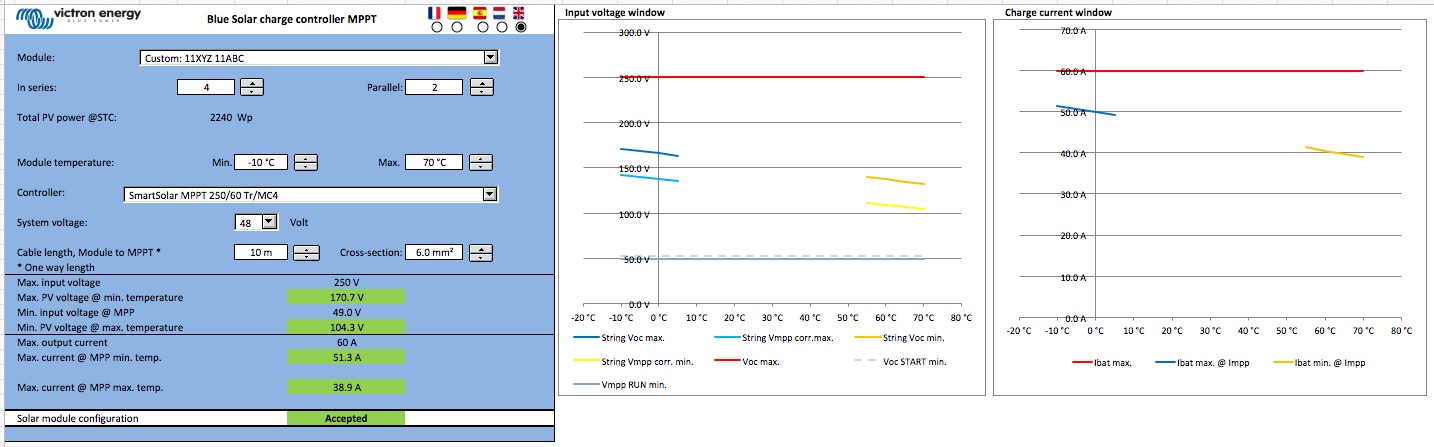

I would go with the 250/60, and connect them in 2 strings of 4s. There is a string calculator excel spreadsheet you can download from Victron, you should check my numbers but here's how they look:

With 4 strings of 2s here's the 150/70. It's technically ok, but minimum Vmp is barely above the minimum voltage for the Controller. It only needs 1V above the battery voltage to keep running, but needs 5V above to start up. Given that your battery voltage will go above 48V, there is really not enough margin there. You are likely have trouble getting it to start up at all on cloudy days. Victron doesn't seem to publish efficiency curves, but often efficiency is also poor when you are so close to the minimum required voltage.

Here is the 250/60 with 2 strings of 4s. Pretty much all right down the middle of the voltage window which is what you like to see. Usually that's where the controller efficiency is optimized. Should have no problems starting up or running under cloudy conditions due to lots of margin above minimum voltage. Also you don't lose any power output vs. the 150/70, as the output current is <60A in both cases.

Rob

|

|

|

03-12-2018, 06:56 PM

03-12-2018, 06:56 PM

|

#42

|

|

Bus Geek

Join Date: Dec 2015

Location: pa

Posts: 2,507

Year: 98

Coachwork: 1. Corbeil & 2. Thomas

Chassis: 1 ford 1998 e350 4x4 7.3 2 mercedes 2004

Engine: 7.3 powerstroke & MBE906

|

I am not in favor of many panels in series. If one has shadow or dirt it pulls them all down. I wired for my 24 volt (lead acid ) system two 12 V

(17 voc) in series and use several cheap mppt controls. My thought behind several controllers and several parallel strings is redundancy and less shadow effects.

Not sure how high you will allow your 48 volt lithium but it can not be a lot above 48 volt.

My current lead set up goes up to 29 volt . you can see some pics of the Dory set up in the thread not a skoolie .

good luck

Later J

|

|

|

03-12-2018, 07:25 PM

03-12-2018, 07:25 PM

|

#43

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

Quote:

Originally Posted by miscrms

I would go with the 250/60, and connect them in 2 strings of 4s. There is a string calculator excel spreadsheet you can download from Victron, you should check my numbers but here's how they look:

With 4 strings of 2s here's the 150/70. It's technically ok, but minimum Vmp is barely above the minimum voltage for the Controller...

Here is the 250/60 with 2 strings of 4s. Pretty much all right down the middle of the voltage window which is what you like to see...

|

Rob, where should I send the check, or maybe PayPal would be preferred? Thank you for the great gauge. I downloaded a copy of that spreadsheet from the Victron site so I could "play" with it. Great information.

|

|

|

03-12-2018, 07:46 PM

03-12-2018, 07:46 PM

|

#44

|

|

Skoolie

Join Date: Aug 2017

Location: Phoenix, AZ

Posts: 228

Year: 1997

Coachwork: Blue Bird

Chassis: AARE 3903

Engine: Cummins 8.3L 12v

Rated Cap: 78

|

Quote:

Originally Posted by joeblack5

I am not in favor of many panels in series. If one has shadow or dirt it pulls them all down. I wired for my 24 volt (lead acid ) system two 12 V

(17 voc) in series and use several cheap mppt controls. My thought behind several controllers and several parallel strings is redundancy and less shadow effects.

Not sure how high you will allow your 48 volt lithium but it can not be a lot above 48 volt.

My current lead set up goes up to 29 volt . you can see some pics of the Dory set up in the thread not a skoolie .

good luck

Later J

|

Eagle, no problem. Glad I could help.

Joe, for smaller systems using smaller panels I agree. IMHO when you get much up over 1000W you really need to start doing longer strings. The OP is putting up about 2300W, so even 4s is still kind of short in my book but seems like a good compromise. Our 3600w bus system with be 2 x 6s strings, and our home 5500w system uses 2x12s strings!

The reasoning is pretty similar to why you'd generally jump from 12v to 24v to 48v battery systems with bigger battery banks / inverters. Efficiency of the conversion electronics generally improves, and wiring losses due to higher current start to add up if you're trying to do a lot of power at low voltage.

You're spot on about partial shade, but with two strings of 4 panels as long as each string is grouped to one end of the bus they should still do pretty well under those conditions. The panels at the end of the bus that's shaded will put out less current, but that would generally happen anyway. If the shading is only on one panel worst case its bypass diodes should kick in to keep partial power out of the shaded string.

Rob

|

|

|

03-12-2018, 10:34 PM

03-12-2018, 10:34 PM

|

#45

|

|

Bus Geek

Join Date: Dec 2015

Location: pa

Posts: 2,507

Year: 98

Coachwork: 1. Corbeil & 2. Thomas

Chassis: 1 ford 1998 e350 4x4 7.3 2 mercedes 2004

Engine: 7.3 powerstroke & MBE906

|

hi Rob, interesting, i guess more a difference of thought, We have 7200 watts on our house all in 4S 9P to charge a 48 volt 1000 ah forklift battery bank and then grid tie. And then we have an additional 1000 watt in direct grid tie

I do not think that the more S has anything to do with your watts as you say but more with the voltage that you want to get to. In case of grid tie you might want to end up with 600 Volt. For a 48 volt system there is no use in going much higher then 60 volt, the higher voltages only gain is lower cable losses because lower currents. With the short runs in a bus I doubt it would add to much.

the case of the shading and diode trick does only work when you have a mppt controller working on that string , but does not work when you have more strings in parallel on the same controller. That is why you, or at least I have multiple controllers in a similar fashion as micro inverters.

just my opinion

Good luck,

later J

|

|

|

03-13-2018, 06:51 AM

03-13-2018, 06:51 AM

|

#46

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

Quote:

Originally Posted by joeblack5

I am not in favor of many panels in series. If one has shadow or dirt it pulls them all down...

|

Quote:

Originally Posted by miscrms

Joe, for smaller systems using smaller panels I agree. IMHO when you get much up over 1000W you really need to start doing longer strings. The OP is putting up about 2300W, so even 4s is still kind of short in my book but seems like a good compromise...

You're spot on about partial shade...

|

Thanks again to both of you guys. This is really good dialogue. I am committed to getting this right, and as I continue to educate myself, this type of discussion helps a lot. I too am (was?) slightly concerned about the shading issues related to panels in series.

I love the Victron spreadsheet because it lets me play around with components and configuration. At this point I see my options as:

1) a 4P2S panel arrangement with a 250/60 charge controller or

2) a 3S3P* panel arrangement with a 150/60 controller

*I would need to source one more matching panel...

|

|

|

03-13-2018, 07:02 AM

03-13-2018, 07:02 AM

|

#47

|

|

Bus Crazy

Join Date: Nov 2011

Location: Sault Ste. Marie, Ontario

Posts: 1,793

Year: 1997

Coachwork: Thomas

Chassis: B3800 Short bus

Engine: T444E

Rated Cap: 36

|

Quote:

Originally Posted by miscrms

Sounds pretty good. I would just be careful about the position of your chimney. You donít really want anything above the level of your panels that is going to create shade on the panels.

|

Park facing east and the chimney will be to the north. Problem solved!

That's how I do it, anyhow.

|

|

|

03-13-2018, 05:44 PM

03-13-2018, 05:44 PM

|

#48

|

|

Skoolie

Join Date: Aug 2017

Location: Phoenix, AZ

Posts: 228

Year: 1997

Coachwork: Blue Bird

Chassis: AARE 3903

Engine: Cummins 8.3L 12v

Rated Cap: 78

|

Quote:

Originally Posted by ComfortEagle

Thanks again to both of you guys. This is really good dialogue. I am committed to getting this right, and as I continue to educate myself, this type of discussion helps a lot. I too am (was?) slightly concerned about the shading issues related to panels in series.

I love the Victron spreadsheet because it lets me play around with components and configuration. At this point I see my options as:

1) a 4P2S panel arrangement with a 250/60 charge controller or

2) a 3S3P* panel arrangement with a 150/60 controller

*I would need to source one more matching panel...

|

I think either is a good solution. More strings means more wiring, more fuses, maybe needing a combiner, etc. As Joe says to fully take advantage you need separate controllers on the strings, so each MPPT is optimizing each string. But even with one controller 3s3p will be somewhat more shade tolerant than 4s2p, and on a bus you might see non-ideal shading situations more often than other installations. On the other hand it may not really end up making that much difference.

By far the most important thing though is to match the panels well to the controller, which either of those configurations should be.

Sent from my iPhone using Tapatalk

|

|

|

03-13-2018, 06:12 PM

03-13-2018, 06:12 PM

|

#49

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

Quote:

Originally Posted by miscrms

I think either is a good solution...

By far the most important thing though is to match the panels well to the controller, which either of those configurations should be.

|

I called the supplier today and the panels hadn't shipped yet so I had them add one more panel to the palette. So, 3S3P it shall be. Of course there won't be any room left on the roof.

I re-measured just to be sure...

|

|

|

03-13-2018, 07:51 PM

03-13-2018, 07:51 PM

|

#50

|

|

Bus Geek

Join Date: Dec 2015

Location: pa

Posts: 2,507

Year: 98

Coachwork: 1. Corbeil & 2. Thomas

Chassis: 1 ford 1998 e350 4x4 7.3 2 mercedes 2004

Engine: 7.3 powerstroke & MBE906

|

Sorry, I thought I had pictures of the charge controllers but i was mistaken.

I used the tracer 2210,one per two panels, they are $79 new or less when used. They go only up to 24 volt. You can still use that if you split you 48 volt in 2x24 volt but that might get a little confusing.

A problem I encountered with the lead acid that when my alternator shorted, the field ran the 24 battery dead. I fixed that and thought that the solar would recharge the battery. It did not recover because the auto select between 24 /12 in the charge controller stayed stuck on the 12 volt setting. Had to learn that the hard way. So now my plan is to run two smaller separate panels directly to each battery so that it will recover by itself if it ever happens again.

With lithium you sure will need more safety shutoffs in there  .

probably I should to  .

Later J

|

|

|

03-15-2018, 05:58 PM

03-15-2018, 05:58 PM

|

#51

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

The solar panel saga continues...

It turns out the warehouse inventory was incorrect and the supplier only had 6 of the 280w panels.

So I now have 8ea of these 325w panels coming. They should be here tomorrow. The supplier sent me this pic along with the bill of lading today.

Based on the specs of these panels and the super handy Victron spreadsheet, I believe I can safely run them in a 2S4P configuration with a 150/70 charge controller.

|

|

|

03-16-2018, 11:01 AM

03-16-2018, 11:01 AM

|

#52

|

|

Bus Crazy

Join Date: Aug 2014

Location: SW New Hampshire

Posts: 1,334

|

Those Hyundai HiS-S325TI 325 Watt Solar Panels are listed at 51 lb each. Add something greater than zero for the mounting hardware. I routinely see people here having indigestion at the thought of putting "hundreds of pounds of weight on the roof" for C-of-G reasons.

Do we have any hard numbers, recommendations, first-person experience with trying to figure out how much weight on the roof is OK and how much is too much? Note that I am explicitly NOT telling the OP that he's crazy to try this, or anything to that effect.

Enquiring minds want to know.

|

|

|

03-16-2018, 12:04 PM

03-16-2018, 12:04 PM

|

#53

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

Quote:

Originally Posted by dan-fox

...Note that I am explicitly NOT telling the OP that he's crazy to try this, or anything to that effect...

|

"Explicitly not" or "not explicitly"...?

I've started a thread here to get us some feedback.

|

|

|

03-16-2018, 12:24 PM

03-16-2018, 12:24 PM

|

#54

|

|

Bus Geek

Join Date: Dec 2015

Location: pa

Posts: 2,507

Year: 98

Coachwork: 1. Corbeil & 2. Thomas

Chassis: 1 ford 1998 e350 4x4 7.3 2 mercedes 2004

Engine: 7.3 powerstroke & MBE906

|

haha

Later J

|

|

|

03-18-2018, 07:41 PM

03-18-2018, 07:41 PM

|

#55

|

|

Bus Crazy

Join Date: Aug 2014

Location: SW New Hampshire

Posts: 1,334

|

Quote:

Originally Posted by ComfortEagle

"Explicitly not" or "not explicitly"...?

I've started a thread here to get us some feedback. |

"explicitly not telling" someone something would cover also not implicitly telling them that thing, or implying it, or innuendo? I was just wondering how much was enough, and how much was too much.

I saw the thread; thanks. Not a lot of content there yet.

|

|

|

03-18-2018, 09:40 PM

03-18-2018, 09:40 PM

|

#56

|

|

Bus Geek

Join Date: Mar 2011

Location: Houston, Texas

Posts: 8,462

Year: 1946

Coachwork: Chevrolet/Wayne

Chassis: 1- 1/2 ton

Engine: Cummins 4BT

Rated Cap: 15

|

Instead of all those panels...just hook up one of these...

A Nuclear Pig! You can probably find one on Ebay.

|

|

|

03-19-2018, 06:13 AM

03-19-2018, 06:13 AM

|

#57

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

Quote:

Originally Posted by dan-fox

"explicitly not telling" someone something would cover also not implicitly telling them that thing, or implying it, or innuendo?

|

Dan, I hope I didn't piss you off, I was only joking. I understand your words. I did note your use of the words ""try this"...

Quote:

Originally Posted by Tango

Instead of all those panels...just hook up one of these...

A Nuclear Pig! You can probably find one on Ebay. |

Nuclear pig, love it. 25w a day for five 5yrs...

|

|

|

03-26-2018, 01:29 PM

03-26-2018, 01:29 PM

|

#58

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

I decided to break the pack down into its seven "battery modules. Technically I didn't need to, but it should make installation and wiring a bit easier. The four smaller modules on the right are the 48V modules, and the larger three on the left are the 64V modules.

I used some big tie ties to keep the tops together and some threaded rod on the bottoms. I used four pieces of threaded rod on each battery with some washers and locknuts. Once tightened I ground off the excess rod. In the pic below the battery on the right is done, but as you can see from the battery on the left, I ran out of threaded rod...

I also ordered a BMS to test out. It is the same unit the guy in this video is using.

I like the idea of being able to monitor the cell voltages and being able to customize some of the parameters. If I wire 2 battery modules in parallel like the video I will still need 4 units.

Finally I am rethinking my inverter choice. I was originally thinking Aims, but this Magnum Energy may be a better choice. With the " optional remote" it says I can custom set a bunch of parameters. In particular the Low Voltage Battery Cut Out (LBCO) can be set as low as 36.0V (for a 48V system). As my "48V" batteries are more like ~45V nominal, the LBCO seems like an important settable parameter. Thanks to all for the continued help and feedback.

|

|

|

04-08-2018, 05:22 PM

04-08-2018, 05:22 PM

|

#59

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

My BMS showed up this week. It was about $80 delivered from China via Russia (Ali Express) so you know it's a quality product (he said sarcastically). It's a 12S 100A BMS with BlueTooth. It has some pretty nice features. I bought one to test it out but if I decide to use it I will be buying three more and running two batteries off of each one.

It looks like they used some "extra solder" to make sure it is able to handle its rated 100A...

I wired it up to a single battery to "test" it out. My inverter won't be here until Thursday so I was limited in terms of testing. I was able to tap into the Volt battery's OEM BMS plug which is nice. The wiring is a mess but it was just a test...

Here is one of the screens from the Android App; a nice snapshot of all cell voltages.

Next weekend I hope to actually hook up a few of the batteries to the BMS and run the inverter. FWIW I went with the Magnum Energy MS4048 Inverter/charger

.

|

|

|

04-11-2018, 08:37 PM

04-11-2018, 08:37 PM

|

#60

|

|

Bus Nut

Join Date: Dec 2017

Location: Southern Maryland

Posts: 505

Year: 1986

Coachwork: Gillig

Chassis: Phantom

Engine: CAT 3208

Rated Cap: 87, says Gillig...

|

So here is what I hope will be the final battery layout.

Also I finally got around to modifying the 64V batteries. Under the goop I cut the copper bus bar isolating the last four cells of the battery module creating a 48V battery and a 16V battery. Three of these 16V battery sections will be wired in series to create the 8th 48V battery.

Physically separating the 16V sections would have difficult, and by not separating them I can re-use the OEM Volt BMS harnesses...

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|