|

|

09-07-2015, 03:46 PM

09-07-2015, 03:46 PM

|

#1

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

Yes, I said that right. 56 30-watt solar panels.

I work for a company that uses 30-watt solar panels. I recently acquired 56 panels from decommissioned units. 3 rows cover 33ft. The entire roof in solar panels. On the Plate:

48 volts

8 Trojan T-105-RE

4 CAT 1000w inverters

1 MorningStar 48V 40A PWM controller

1 Krieger 2000w (attached to enigine for bedroom A/C)

Runs:

1 Food processor for Baby Food

1 Sundanzer DCR225 refrigerator

3 LED Strip lighting

Occasional A/C

2 laptops

2 Cell phones

1 Tablet

|

|

|

09-07-2015, 03:50 PM

09-07-2015, 03:50 PM

|

#2

|

|

Bus Geek

Join Date: Aug 2011

Location: Stony Plain Alberta Canada

Posts: 2,937

Year: 1992

Coachwork: Bluebird

Chassis: TC2000 FE

Engine: 190hp 5.9 Cummins

Rated Cap: 72

|

Sweet, about time someone set up a good size solar array.

Why 4 inverters, VS one larger good one?

Nat

__________________

"Don't argue with stupid people. They will just drag you down to their level, and beat you up with experience."

Patently waiting for the apocalypses to level the playing field in this physiological game of life commonly known as Civilization

|

|

|

09-07-2015, 04:02 PM

09-07-2015, 04:02 PM

|

#3

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

Great question. The most affordable inverters per watt are 1000w x 12v. I'm running 48v and need 4 to balence the load across each 12v set. Also, when we get back to our business in Nicaragua we will break the system into 4 - 12v parts. In the bus I'll run two 15A A/C breakers in a distribution box. One for A/C and the other for the rest.

|

|

|

09-16-2015, 12:12 PM

09-16-2015, 12:12 PM

|

#4

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

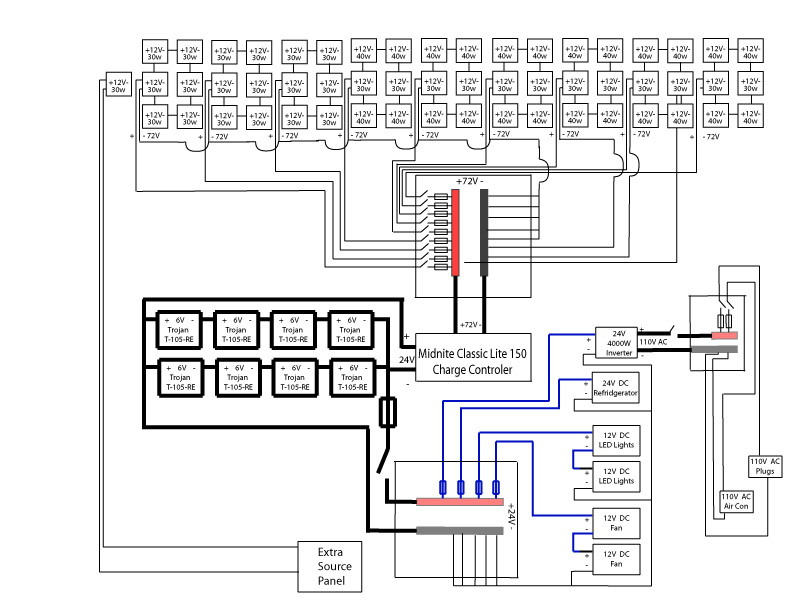

Here is the first draft of the Solar Array Schematic. You will have to click the link for the higher resolution .pdf. https://eljardinometepe.files.wordpr...lar-system.pdf

|

|

|

09-16-2015, 01:57 PM

09-16-2015, 01:57 PM

|

#5

|

|

Bus Crazy

Join Date: Feb 2012

Location: Salt Lake City Utah

Posts: 1,635

Year: 2000

Chassis: Blue Bird

Engine: ISC 8.3

|

Wow, that's.. interesting. I have to admit, it's an unusual combination of 8 T-105 batteries and a Xantrex charge controller, which are relatively premium or at least solid upper- to high-end stuff, with low-wattage panels and cheapest-per-watt inverters. I'm not saying it can't work; just that more often a system is high-end all the way through or cheap all the way through so this is just unexpected.

Anyway, I see a few small problems in the schematic:

- the battery bank is shorted. The batteries are strung in series for charging, but the pairs are also in parallel for discharging. There's a short circuit where the right-most battery negative connects to the gray bus bar and the third-from-right connects to that same bar. This creates a short circuit around the two right-most batteries (and so on across the rest of the array). Basically what you're building here is a charge pump with batteries instead of capacitors. Charge pumping is a common voltage conversion technique, but you'll need to add switches to break up the series string into 12 volt pairs, and switches to connect the pairs to the bus bar. The switches have to alternate: close the switches to make the series loop for charging and open the switches going to the 12v bus bars, then open the series switches and close the bus switches so that you can discharge. Obviously that presents a problem if you need to draw power from the bank during the day because it reduces the time spent charging. There are work-arounds for this too, but anyway my point is just that the schematic doesn't show the synchronized switches that are needed to make the battery bank part work out the way I think you're wanting it to work. Maybe also consider adding charge equalization across the 12v pairs? I know they'll be switched into parallel mode and intuitively the charge would equalize as a result, but given that you have to raise the voltage to almost 14v to really drive charge into a 12v lead battery, I wonder whether simply wiring in parallel is enough in practice to truly equalize them. I have no idea.

- inverters in parallel: not all inverters advertise this capability. I don't know whether it usually works anyway even on those that don't advertise it, but I assume you already picked a model you're sure supports this mode.

- AirCon: can't quite tell what is the objective here.. maybe for the A/C to run off the solar or the bus battery? Needs more switches so that the inverters on the two sides don't end up in a fight or back-feeding a supposed-dead circuit. Also consult the bus battery and alternator to see how they feel about this (we've had other threads about driving an ac-powered aircon from an inverter off the alternator, and usually concluded the aircon was too big and power hungry for this to make sense).

- 24v fridge and misc 12v loads: what is this portion trying to do? One could put two 12v loads in series across a 24v supply and at least have a prayer of working (so long as power consumption in both loads was guaranteed equal). But this part is confusing. Both terminals of the 24v fridge are connected to the gray 12v bus bar..

Summary: it needs a little refinement, but the concepts are basically sound and it's a creative solution. Good work.

|

|

|

09-16-2015, 05:50 PM

09-16-2015, 05:50 PM

|

#6

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

Primary design restrictions:

Keep total installation cost down

56 - 30w (2A) panels were free from a demolition project at work

25 - 12v 4A Morningstar charge controllers also free but didn't work them in.

I'll break the system down into smaller zones when we arrive back at the farm

Insects in the tropics are almost impossible to keep out of vented electronics like inverters and therefore need to be replaced often. The fridge can run on 12v or 24v. Other 12v lines are LED Rope lighting, the heater fans, and USB charging ports.

The aircon happend when I said off hand that it was probably enough solar panels to run an aircon. The hope was that it would mostly run when the bus was running and not off the solar. In the end it won't run once back on the farm so it is of lowest priority.

All that being said, in other forums I may be considering running an outback power charge controller eliminating the step down issues. Maybe wire the panels at 96v and the batteries at 24v. Then using 24v inverters to simplify the system further.

|

|

|

09-16-2015, 09:34 PM

09-16-2015, 09:34 PM

|

#7

|

|

Bus Geek

Join Date: Aug 2011

Location: Stony Plain Alberta Canada

Posts: 2,937

Year: 1992

Coachwork: Bluebird

Chassis: TC2000 FE

Engine: 190hp 5.9 Cummins

Rated Cap: 72

|

If running Ac from the bus alternator, make sure you have a med, or large frame alt. A small frame unit will have a really low duty cycle and will burn out in no time.

Large frame 250 amp should be the minimum when running AC from the alternator if you want it to last.

Same go's for people trying to charge their house batteries from the alternator.

Nat

__________________

"Don't argue with stupid people. They will just drag you down to their level, and beat you up with experience."

Patently waiting for the apocalypses to level the playing field in this physiological game of life commonly known as Civilization

|

|

|

09-17-2015, 06:32 AM

09-17-2015, 06:32 AM

|

#8

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

I'll check on the alternator and see what size it is. I'm assuming that the size or quantity of alternators is what allow for top mount A/C on Coaches, Motorhomes and box truck refrigeration?

|

|

|

09-17-2015, 07:25 AM

09-17-2015, 07:25 AM

|

#9

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

I looks like a standard size alternator. I couldn't find any real markings. There is an ideler pulley bellow that looks to have identical mounts as the top alternator presumably holding the spot for a second alternator. Now the question becomes, would all that money to tie it into the solar and bus be better spent on an isolated gen set that could run the aircon or other occasional high draw devises such as power tools.

Again, after it's 6000 mile journey south it will put up on blocks to retire as a house/hostel dormitory and never drive again.

|

|

|

09-17-2015, 11:31 AM

09-17-2015, 11:31 AM

|

#10

|

|

Bus Crazy

Join Date: Feb 2012

Location: Salt Lake City Utah

Posts: 1,635

Year: 2000

Chassis: Blue Bird

Engine: ISC 8.3

|

Vocational vehicles where the refrigeration is often needed but is only needed while the vehicle is driving (passenger A/C or refrigerated cargo box) generally have a compressor driven directly off an engine. Fans don't need much power compared to the compressor, and they're electric. Those that need full-time refrigeration are usually done this way too but with an auxiliary engine that can be left running when the propulsion engine is off (reefer trailers for example). The compressor needs energy in a mechanical motion form; if that energy can be taken directly from a moving engine then it's more efficient (as compared to energy from moving engine to electricity, then electricity back to motion).

Seems to me that motorhomes often have a little bit of engine-driven A/C in the dash but the rooftop units are driven by an aux generator while underway (if desired).

If it'll just be parked forever at the end of the drive then maybe you don't need to worry about the longevity of the alternator.. so long as it survives the trip. Or you could pack a generator for the A/C and sell it or remove it for other uses when the bus is finally parked and plugged into grid power somewhere.

|

|

|

10-11-2015, 06:10 PM

10-11-2015, 06:10 PM

|

#11

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

I have simplified the system a little bit. I justified the cost of the MPPT controller based on the savings in wiring the panels in 72 volt configuration.

|

|

|

10-11-2015, 06:14 PM

10-11-2015, 06:14 PM

|

#12

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

I have the center row now mounted on top. I used a 1" angle aluminum from Grainger. It was the cheapest structural material I could find and light to boot. It feels really ridge and rocks the whole bus if you try to wiggle it.

|

|

|

10-11-2015, 06:15 PM

10-11-2015, 06:15 PM

|

#13

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 06:16 PM

10-11-2015, 06:16 PM

|

#14

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 06:17 PM

10-11-2015, 06:17 PM

|

#15

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 06:17 PM

10-11-2015, 06:17 PM

|

#16

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 06:18 PM

10-11-2015, 06:18 PM

|

#17

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 06:18 PM

10-11-2015, 06:18 PM

|

#18

|

|

Skoolie

Join Date: Jun 2015

Location: Rhode Island/Nicaragua

Posts: 107

Year: 1997

Coachwork: Thomas

Chassis: Freightliner

Engine: CAT 3126 7.2L

Rated Cap: 78

|

|

|

|

10-11-2015, 11:55 PM

10-11-2015, 11:55 PM

|

#19

|

|

Bus Geek

Join Date: Aug 2011

Location: Stony Plain Alberta Canada

Posts: 2,937

Year: 1992

Coachwork: Bluebird

Chassis: TC2000 FE

Engine: 190hp 5.9 Cummins

Rated Cap: 72

|

Sweet setup.

I love the way you made the front angled for better aerodynamics.

About time some one built a decent size solar array.

Nat

__________________

"Don't argue with stupid people. They will just drag you down to their level, and beat you up with experience."

Patently waiting for the apocalypses to level the playing field in this physiological game of life commonly known as Civilization

|

|

|

10-12-2015, 01:00 AM

10-12-2015, 01:00 AM

|

#20

|

|

Bus Nut

Join Date: Sep 2013

Location: Denver

Posts: 489

Year: 1982

Coachwork: Blue Bird

Chassis: International S1800

Engine: DT466 Trans: MT643

Rated Cap: 65

|

so do those panels have a cover over them? i see some kind of rounded plastic looking thing. If that's the case, that must wreak havoc on their output--I have 1200 watts of panels, and the highest output ive ever seen them give me is around 900 watts. if there is any dirt/debris on them, the power drops quickly--id do some testing and see how much power you're actually getting out of those panels. you might want to try and find a way to replace that cover if you can.

Im also running a midnite cc and 8x t105 batteries with a 24v inverter. its an awesome setup and it runs everything i need easily. i never worry about my power and i can even run my welder for short periods of time!

great idea about running 12v loads in series to make 24v--ive been looking at 24->12v step down converters

do you have plans for a breaker box of some kind? how are you combining your solar panels? I used a rooftop combiner box and a dc load box with 175 amp breaker.

also, have you picked out your battery cables yet?? that's an expensive item that you don't want to skimp on.

__________________

Patina enthusiast and professional busman

www.bustoshow.org

Blog: www.lookatthatbus.com

Instragram: @lookatthatbus

|

|

|

|

|

| Thread Tools |

|

|

| Display Modes |

Linear Mode Linear Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

» Recent Threads

» Recent Threads |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|